Usually we copy the Piping department when it comes to flange rating but as always copying without understanding can lead to catastrophic safety hazard

Basics of flange rating:- Where do flange ratings come from?

Well this rating come from the following ASME standards *Note 1

1.ASME B16.5 (if pipe size is less than 24 inches )

2.ASME B16.47(if pipe size is greater than 24 inches)

Every material has a certain limit of pressure and temperature it can withstand so we have the Pressure Temperature tables in this standard

In simple words :-They describe at a particular rating how much Pressure and Temperature it can withstand.

The Higher the rating the more pressure & temperature the flange can withstand.

1.ASME B16.5 (if pipe size is less than 24 inches )

2.ASME B16.47(if pipe size is greater than 24 inches)

Every material has a certain limit of pressure and temperature it can withstand so we have the Pressure Temperature tables in this standard

In simple words :-They describe at a particular rating how much Pressure and Temperature it can withstand.

The Higher the rating the more pressure & temperature the flange can withstand.

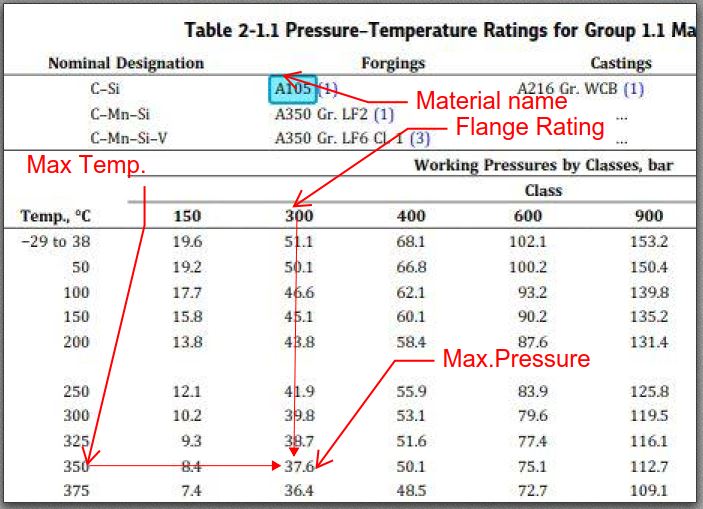

Enough of theory let’s take a practical Example

(Understanding How to practically use ASME B16.5)

Lets take a Carbon Steel (A106) flange with rating 300#

I derived from this standard that 300# carbon steel flange can withstand 37.6 Bar of pressure at 350 Deg C.

How to use this Standard ?

Refer a Snippet below from the Standard

I derived from this standard that 300# carbon steel flange can withstand 37.6 Bar of pressure at 350 Deg C.

How to use this Standard ?

Refer a Snippet below from the Standard

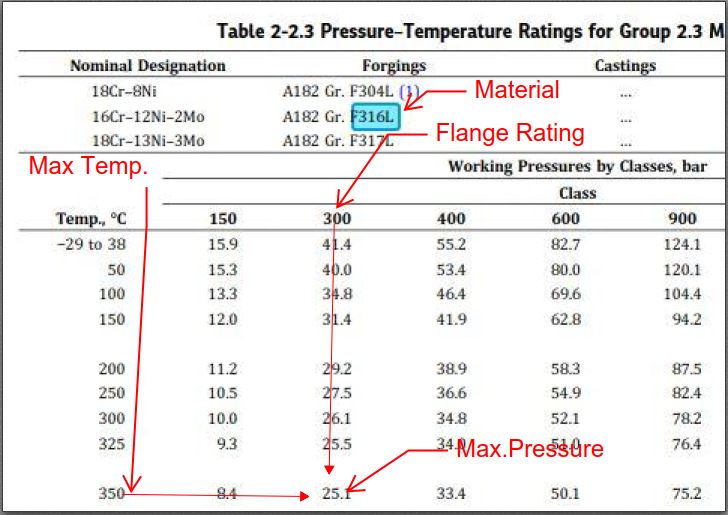

Here’s the Catch !!!!

For same 300 Class of flange

The material stainless Steel (SS316L) can withstand 25.1 Bar of pressure at 350 Deg C.

For same 300 Class of flange

The material stainless Steel (SS316L) can withstand 25.1 Bar of pressure at 350 Deg C.

Do you see the difference ?

For same class 300 flange at 350 Deg C, SS316L can only withstand 25.1 Bar while CS A105 can withstand 37.6 Bar !!!!!

But if you compare the corrosion resistance YES ! SS316L is more corrosion resistant than CS A105 as it has very low carbon content .

In one of my projects Hydrocracker unit which had High Pressure &Temperature majority of SS flanges did not fit in the PT rating hence higher Flange rating had to be used and the same had to be informed to piping that even they have to do the same !!

(So that both flanges are of same dimensions )

So be safe, keep you plant/Project Safe and always check PT ratings in ASME B16.5/16.47 !!!

I hope this article has been helpful

Note 1:- There is also DIN piping standard called 1092-1. In this the flange ratings are mentioned in PN rating. Like PN 10 etc

PS: This is as per best of my current understanding

For same class 300 flange at 350 Deg C, SS316L can only withstand 25.1 Bar while CS A105 can withstand 37.6 Bar !!!!!

But if you compare the corrosion resistance YES ! SS316L is more corrosion resistant than CS A105 as it has very low carbon content .

In one of my projects Hydrocracker unit which had High Pressure &Temperature majority of SS flanges did not fit in the PT rating hence higher Flange rating had to be used and the same had to be informed to piping that even they have to do the same !!

(So that both flanges are of same dimensions )

So be safe, keep you plant/Project Safe and always check PT ratings in ASME B16.5/16.47 !!!

I hope this article has been helpful

Note 1:- There is also DIN piping standard called 1092-1. In this the flange ratings are mentioned in PN rating. Like PN 10 etc

PS: This is as per best of my current understanding

If you found this valuable and wish to receive a new technical article every alternate weekend and one inspirational article every month you could join the Articles newsletter.