Introduction:-

This particular thermowell had failed during wake frequency calculation and thus the dimensions of thermowell were being modified.

An Error popped up while performing this thermowell wake frequency calculation.

It said Taper ratio violation

Well let’s explore what this error means and what is the significance of taper ratio in thermowell.

An Error popped up while performing this thermowell wake frequency calculation.

It said Taper ratio violation

Well let’s explore what this error means and what is the significance of taper ratio in thermowell.

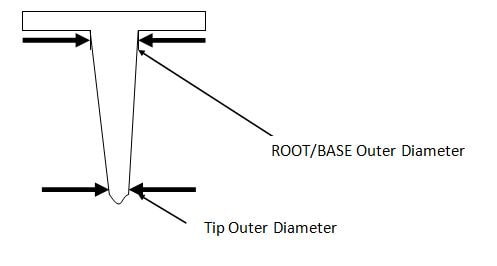

Taper profile/ratio

This is applicable for Tapered thermowell designs which are the most commonly used thermowell designs in process industries.

Taper profile is ratio of O.D of thermowell at Tip to the OD of thermowell at base.

The below diagram depicts the thermowell taper profile

Taper profile is ratio of O.D of thermowell at Tip to the OD of thermowell at base.

The below diagram depicts the thermowell taper profile

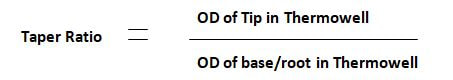

Taper ratio criteria mentioned in ASME PTC 19.3

ASME PTC 19.3 is one of the most widely used standard for thermowells and preferred by many end users around the world.

In order for the thermowell to comply and be covered within ASME PTC 19.3 this ratio must be in range of 0.58 to 1.

In order for the thermowell to comply and be covered within ASME PTC 19.3 this ratio must be in range of 0.58 to 1.

How to decide tapper profile?

One of the guidelines to follow is PIP thermowell fabrication standard PIP PCFTE100.

PIP PCFTE100 has recommended dimensions for thermowell and thus can be used as starting point.

If the thermowell passes WFC calculation then the same dimensions can be retained else we need to apply various solution so that thermowell passes the calculation.

One of the solutions is to iterate the thermowell dimensions so that it passes this WFC criteria.

While modifying this length we must take care that the taper ratio criteria as described in ASME PTC 19.3 is met.

PIP PCFTE100 has recommended dimensions for thermowell and thus can be used as starting point.

If the thermowell passes WFC calculation then the same dimensions can be retained else we need to apply various solution so that thermowell passes the calculation.

One of the solutions is to iterate the thermowell dimensions so that it passes this WFC criteria.

While modifying this length we must take care that the taper ratio criteria as described in ASME PTC 19.3 is met.

How to calculate taper ratio :- A practical example

Let us take a typical example

The Outer diameter at the Base of thermowell is recommended in PIP PCFTE100 to be 1.0625 inches

The Outer diameter at the tip of thermowell is recommended in PIP PCFTE100 to be 5/8”=0.625 inches

Thus The Taper ratio is calculated as follows

Taper ratio = 0.625/1.0625 = 0.58

Thus we observe that a thermowell fabricated as per PIP standard complies with the taper ratio requirement provided in ASME PTC 19.3

However these dimensions get modified if the thermowell fails WFC calculation hence when you modify the OD of the base of thermowell reconfirm whether that it passes WFC calculation.

The Outer diameter at the Base of thermowell is recommended in PIP PCFTE100 to be 1.0625 inches

The Outer diameter at the tip of thermowell is recommended in PIP PCFTE100 to be 5/8”=0.625 inches

Thus The Taper ratio is calculated as follows

Taper ratio = 0.625/1.0625 = 0.58

Thus we observe that a thermowell fabricated as per PIP standard complies with the taper ratio requirement provided in ASME PTC 19.3

However these dimensions get modified if the thermowell fails WFC calculation hence when you modify the OD of the base of thermowell reconfirm whether that it passes WFC calculation.

Is this requirement compliant even after WFC calculation?

Majority of sizing tools (eg:- SPI calculation module) cover this criteria and if the user violates this taper ratio and error message gets popped up.

However if you are performing a manual calculation for a tricky cases then do keep in mind not to violate this taper ratio requirement else your design would not be covered under ASME PTC 19.3.

However if you are performing a manual calculation for a tricky cases then do keep in mind not to violate this taper ratio requirement else your design would not be covered under ASME PTC 19.3.

Why is tapper profile important?

This is important since further reduction in taper ratio beyond 0.58 will affect the strength retaining capacity of thermowell.

Thermowell face von Karman vortex all the time and hence it is important to ensure that thermowell can withstand those vortex for a sustained period of time without cracking.

Also note that a broken thermowell is a serious concern to safety of other instruments and systems as well.

Thermowell face von Karman vortex all the time and hence it is important to ensure that thermowell can withstand those vortex for a sustained period of time without cracking.

Also note that a broken thermowell is a serious concern to safety of other instruments and systems as well.

In conclusion

Major of clients around the world emphasis compliance to ASME PTC 19.3 standard and respecting the taper profile ratio would ensure that the thermowell design is compliant with the standard.

Also,The integrity of the thermowell can be ensured since a taper ratio below 0.58 can lead to cracking of thermowell in the long run and cause serious concerns to the safety of plant and people.

Hence always ensure that your thermowell has a taper ratio between 0.58 to 1.

Also,The integrity of the thermowell can be ensured since a taper ratio below 0.58 can lead to cracking of thermowell in the long run and cause serious concerns to the safety of plant and people.

Hence always ensure that your thermowell has a taper ratio between 0.58 to 1.

Thanks for reading.

Hope you found it valuable.

Also, Here's a free E-book on diaphragm seal systems that cover practical industrial lessons and safety tip for engineering great diaphragm seal systems.

Hope you found it valuable.

Also, Here's a free E-book on diaphragm seal systems that cover practical industrial lessons and safety tip for engineering great diaphragm seal systems.