What is meant by full vacuum and can it destroy a chemical plant?

A shocked pharma plant worker built up the courage and reported to his supervisor “All the medicine that has been prepared by our plant today has to be flushed out as waste”

“What, are you kidding! You mean all of it?” the supervisor enquired

“Yes, it seems all the medicines produced today are facing quality rejection, The Q.A reports suggests these are contaminated” the worker replied

“Well, this is serious. What could have possibly gone wrong? All the procedures were followed, as a pharma company our reputation could be at stake here”

Before we get into the investigation and figure out how as an engineer, we can avoid such a situation.

Let us brush up some basic principles of physics so we can appreciate the findings of the investigation that took place for the above incident

“What, are you kidding! You mean all of it?” the supervisor enquired

“Yes, it seems all the medicines produced today are facing quality rejection, The Q.A reports suggests these are contaminated” the worker replied

“Well, this is serious. What could have possibly gone wrong? All the procedures were followed, as a pharma company our reputation could be at stake here”

Before we get into the investigation and figure out how as an engineer, we can avoid such a situation.

Let us brush up some basic principles of physics so we can appreciate the findings of the investigation that took place for the above incident

What is Full Vacuum?

Full vacuum means the complete absence of pressure and is also called as Absolute Pressure or absolute Zero pressure.

On earth we experience atmospheric pressure which is approximately 14.7 Psia (The “a” here stands for absolute pressure)

Note: - Approximate because atmospheric pressure on earth varies as per altitude

So Full vacuum would be 0 Psia.

Typical example: Astronauts wearing space suits

In space there is not atmospheric pressure hence full vacuum exists and astronauts there use a pressurized space suit.

If they would not use a pressurized space suit, then as you know our bodies produce pressure and there would be no external pressure to balance it and this would cause the nerves of our body to expand and eventually lead to death.

On earth we experience atmospheric pressure which is approximately 14.7 Psia (The “a” here stands for absolute pressure)

Note: - Approximate because atmospheric pressure on earth varies as per altitude

So Full vacuum would be 0 Psia.

Typical example: Astronauts wearing space suits

In space there is not atmospheric pressure hence full vacuum exists and astronauts there use a pressurized space suit.

If they would not use a pressurized space suit, then as you know our bodies produce pressure and there would be no external pressure to balance it and this would cause the nerves of our body to expand and eventually lead to death.

How is Vacuum condition created on earth or in our process plants by steam?

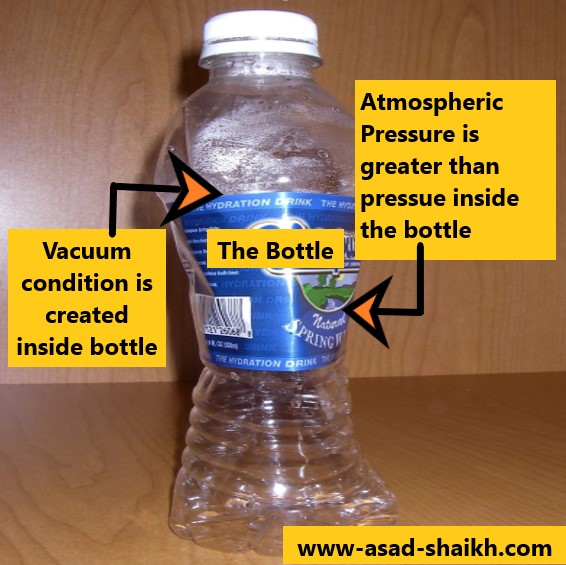

I tried a small experiment at home!!

I took steamy hot water, poured it in a plastic bottle, tightly closed the lid and kept it in freezer.

What Happened?

The plastic bottle buckled up!

I took steamy hot water, poured it in a plastic bottle, tightly closed the lid and kept it in freezer.

What Happened?

The plastic bottle buckled up!

But Why did this happen?

In Gases the molecules are far apart from each other as compared to liquids or solids. And we know Steam is gaseous state of water.

What will happen when steam is cooled in an air-tight container?

Condensation will take place and the molecules will come closer to each other as steam turns to water.

But there is not leak or space for atmosphere to fill in this empty place, so vacuum gets created.

Since the internal pressure is lower (due to vacuum) than the outer atmospheric pressure, the outer atmospheric pressure deforms the bottle.

What will happen when steam is cooled in an air-tight container?

Condensation will take place and the molecules will come closer to each other as steam turns to water.

But there is not leak or space for atmosphere to fill in this empty place, so vacuum gets created.

Since the internal pressure is lower (due to vacuum) than the outer atmospheric pressure, the outer atmospheric pressure deforms the bottle.

What is meant by steam out condition?

The pipes and equipment must be cleaned at regular intervals and one of the methods is steam cleaning.

During this process steam is release into the pipe and equipment at a designated pressure and temperature called steam out condition.

Usually our systems(pipes) are closed such that atmospheric air cannot enter and when steam cleaning is done.

Quite a few times after steam cleaning the steam remains in the closed system and eventually cools forming vacuum inside the pipes or equipment.

During this process steam is release into the pipe and equipment at a designated pressure and temperature called steam out condition.

Usually our systems(pipes) are closed such that atmospheric air cannot enter and when steam cleaning is done.

Quite a few times after steam cleaning the steam remains in the closed system and eventually cools forming vacuum inside the pipes or equipment.

What happened in the pharma plant?

The day before the accident the Batch reactor was steam cleaned.

After stem cleaning the operator closed all the inlet and outlet valves of the equipment.

Thus the steam remained inside the equipment and eventually during the whole night the steam cooled, and thus Hard vacuum was created inside the equipment.

The diaphragm seals used to measure pressure of the equipment were not designed to handle such high vacuum conditions and the membranes buckled up!!

This caused the Fill fluid inside the diaphragm seal to be spilled in the equipment and thus the entire batch of medicine produced during the following day was contaminated from this fill fluid.

After stem cleaning the operator closed all the inlet and outlet valves of the equipment.

Thus the steam remained inside the equipment and eventually during the whole night the steam cooled, and thus Hard vacuum was created inside the equipment.

The diaphragm seals used to measure pressure of the equipment were not designed to handle such high vacuum conditions and the membranes buckled up!!

This caused the Fill fluid inside the diaphragm seal to be spilled in the equipment and thus the entire batch of medicine produced during the following day was contaminated from this fill fluid.

What precaution should we take as instrumentation engineers?

If we know a stem out or potential vacuum condition could be created one obvious precautionary step is to specify instruments for full vacuum conditions.

Also remember, quite a few control valve packing materials, Mag flow meter liners cannot withstand full vacuum condition and they collapse under vacuum.

Finally torque calculation for On-off valves are also influence by presence of vacuum since it would require more torque for valve to open in the presence of vacuum condition.

A similar incident’s have also taken place in Pulp and paper industry when condensation of gases inside the equipment let to vacuum condition.

The vacuum condition forces the atmospheric air to enter the equipment through vacuum relief valve which lead to creation of an explosive mixture, eventually leading to an explosion and lead to death and injury.

Hope this article has been of value to you.

Also remember, quite a few control valve packing materials, Mag flow meter liners cannot withstand full vacuum condition and they collapse under vacuum.

Finally torque calculation for On-off valves are also influence by presence of vacuum since it would require more torque for valve to open in the presence of vacuum condition.

A similar incident’s have also taken place in Pulp and paper industry when condensation of gases inside the equipment let to vacuum condition.

The vacuum condition forces the atmospheric air to enter the equipment through vacuum relief valve which lead to creation of an explosive mixture, eventually leading to an explosion and lead to death and injury.

Hope this article has been of value to you.

"FREE E-Book on one of the most crucial topic in Engineering"

"Engineering Standards"

Credits:-I learnt about this concept from Mick Vermeer, a highly knowledgeable yet humble I&C engineer with experience of almost 3 decades currently residing in the Netherlands.

References

1.API RP 551 Standard Page 79, 149

2.USCSB -US chemical safety board for the pulp and paper accident report

Details of the incident about the pharma company like name of company, Year of accident are not disclosed due to confidentiality reasons to protect brand name. The only reason to share this incident was to derive lessons learnt and prevent such failures to occur in other plants and these details are irrelevant for learning perspective.

References

1.API RP 551 Standard Page 79, 149

2.USCSB -US chemical safety board for the pulp and paper accident report

Details of the incident about the pharma company like name of company, Year of accident are not disclosed due to confidentiality reasons to protect brand name. The only reason to share this incident was to derive lessons learnt and prevent such failures to occur in other plants and these details are irrelevant for learning perspective.

| Download the pdf version of article for future use |