Fill Fluid Vaporization

Concept of Fill Fluid vaporization

Do you believe that water always boils at 100°C?

Do you still believe it is true?

Well this statements needs rectification water boils at 100°C at Atmospheric pressure.

As per whitepaper published by badotherm a well know vendor and an expert in diaphragm seal systems stated that water can boil at even ~0°C when pressure reduces to Full vaccum.

It is a mandatory requirement to have the fill fluid in liquid state under all process conditions if the fill fluid turns to vapour state then the diaphragm seal system will cease to work correctly.

This is because the diaphragm seal system works on the principle that liquids are incompressible and thus transfer pressure from process side to transmitter.

However gases are compressible and would absorb some pressure thus tranmitter would show incorrect reading.

Do you still believe it is true?

Well this statements needs rectification water boils at 100°C at Atmospheric pressure.

As per whitepaper published by badotherm a well know vendor and an expert in diaphragm seal systems stated that water can boil at even ~0°C when pressure reduces to Full vaccum.

It is a mandatory requirement to have the fill fluid in liquid state under all process conditions if the fill fluid turns to vapour state then the diaphragm seal system will cease to work correctly.

This is because the diaphragm seal system works on the principle that liquids are incompressible and thus transfer pressure from process side to transmitter.

However gases are compressible and would absorb some pressure thus tranmitter would show incorrect reading.

Practical Example from the Industrial World

Let’s take Emerson (Rosemount) Diaphragm seal systems.

They have a variety of Diaphragm seal Fill Fluid to select as per our requirement.

let us select Silicone 200 since it is one of the most common fill fluid used in the Industry. Industry.

They have a variety of Diaphragm seal Fill Fluid to select as per our requirement.

let us select Silicone 200 since it is one of the most common fill fluid used in the Industry. Industry.

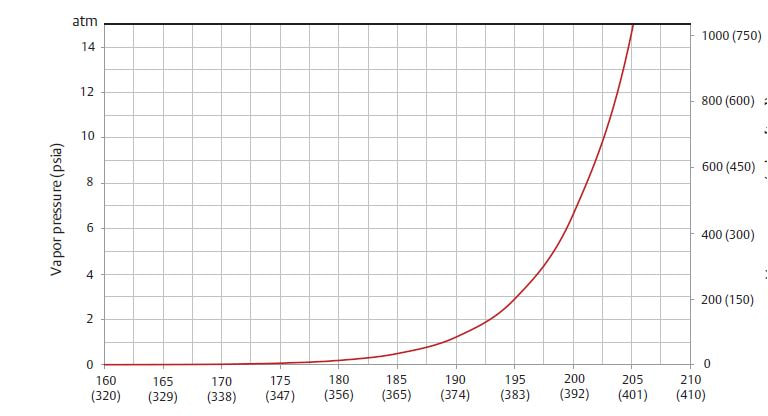

How to read Pressure Temperature Graphs

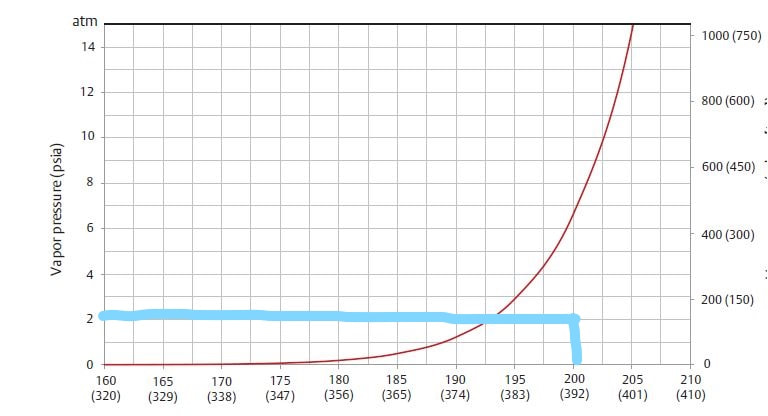

Below is the graph taken from Vendor Emerson (Rosemount-1199-fill-fluid-specifications-en-74338)

The Blue Region shaded is where the Fill fuid stays in Liquid state.

The Red region denotes the region where the fill fuid is in vapour state.

Our aim is to have the full fluid in the blue range for accurate working of diaphragm seals.

The Red region denotes the region where the fill fuid is in vapour state.

Our aim is to have the full fluid in the blue range for accurate working of diaphragm seals.

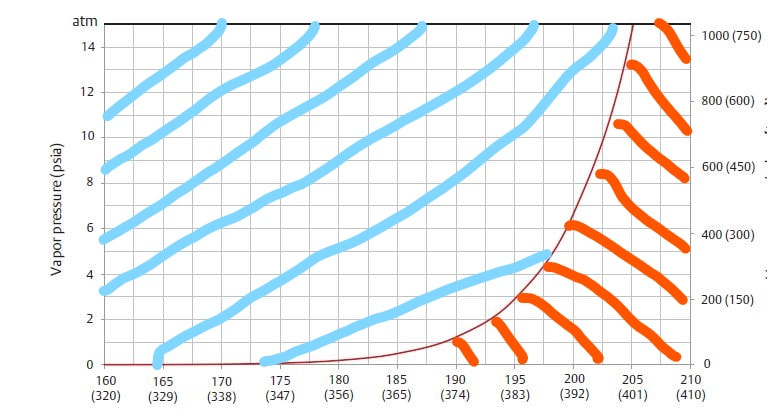

Let us have 2 cases:-

Case 1: The fill Fluid is suitable for the process pressure and temperature parameters

The Lower Design Pressure of the process is 10 Psia

And the Design Temperature is 180 Deg C

Thus we get the following point of intersection

And the Design Temperature is 180 Deg C

Thus we get the following point of intersection

This states that Fill fluid will remain in Liquid state despite the extreme design conditions of the process.

Hence the fill fluid is suitable for our process condition.

Hence the fill fluid is suitable for our process condition.

Case 2: The Fill fluid is unsuitable for the process pressure and temperature parameters

The Lower Design Pressure of the process is 2 Psia

And the Design Temperature is 200 Deg C

Thus we get the following point of intersection

And the Design Temperature is 200 Deg C

Thus we get the following point of intersection

This states that Fill fluid will not remain in Liquid state, It would turn to gaseous state and thus diaphragm seal would not be able to translate the process pressure since gases are compressible in nature.

Hence the fill fluid is not suitable for our process condition.

Hence the fill fluid is not suitable for our process condition.

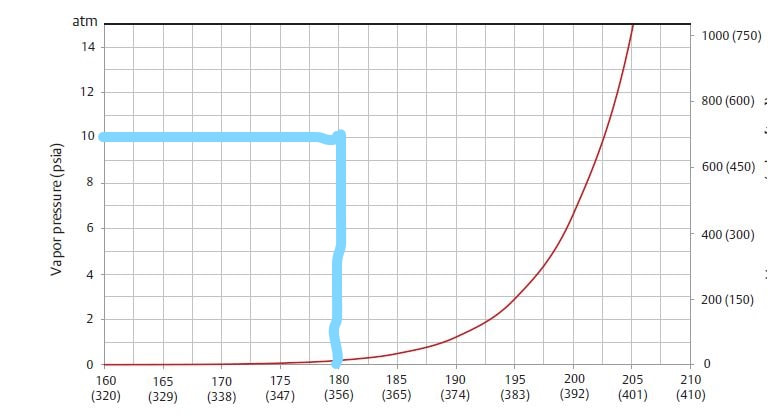

Solution:-

The Fill fluid must be changed and then the intersection point must be checked for the fill fluid staying in liquid state for all the conditions.

Hence lets select silicone 704 as our fill fluid.

Here it is observed that for our design conditions the fill fluid will stay in liquid state and thus can be selected for our process conditions.

Hence lets select silicone 704 as our fill fluid.

Here it is observed that for our design conditions the fill fluid will stay in liquid state and thus can be selected for our process conditions.

Note: Silicone 200 oil itself has various grades so always confirm from your respective vendor.

Example : The Silicone 200 Grade of Emerson and Endress+Hauser had slight differences in operating temperature limit.Hence it is recommended to refer technical graphs of respective vendors or enquire the vendor to provide graphs if they have not published the same online.

Thanks for reading.

Hope it has been of value to you.

Example : The Silicone 200 Grade of Emerson and Endress+Hauser had slight differences in operating temperature limit.Hence it is recommended to refer technical graphs of respective vendors or enquire the vendor to provide graphs if they have not published the same online.

Thanks for reading.

Hope it has been of value to you.