Below we start lets us look at what international standards have to say about thermowell U-Length

Thermowell Tip must be at least 2 mm immersed in Liquid (As per API 551)

Also, For 2-phase service PIP Standard's Temperature Measurement criteria recommendeds that Tip must be all the way up to Liquid phase for better measurement ()

Also, as a rule of thumb it said that Thermowell must go all the way to 1/3 rd of the pipe.

This can be known as per the client design basis of the project.

Now we would look at a factor which is missed a lot of time during thermowell U-Length Calculation.

Does change in insulation affect the Thermowell U-Length?

Yes it does!!

Thermowell Tip must be at least 2 mm immersed in Liquid (As per API 551)

Also, For 2-phase service PIP Standard's Temperature Measurement criteria recommendeds that Tip must be all the way up to Liquid phase for better measurement ()

Also, as a rule of thumb it said that Thermowell must go all the way to 1/3 rd of the pipe.

This can be known as per the client design basis of the project.

Now we would look at a factor which is missed a lot of time during thermowell U-Length Calculation.

Does change in insulation affect the Thermowell U-Length?

Yes it does!!

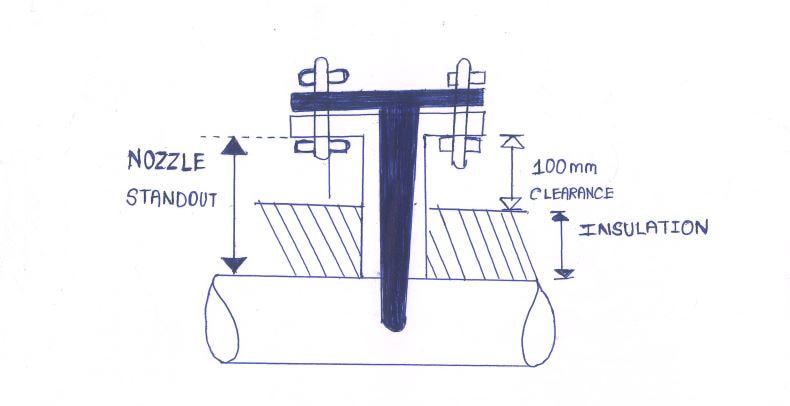

Recommended Practice (Helpful during Maintenance)

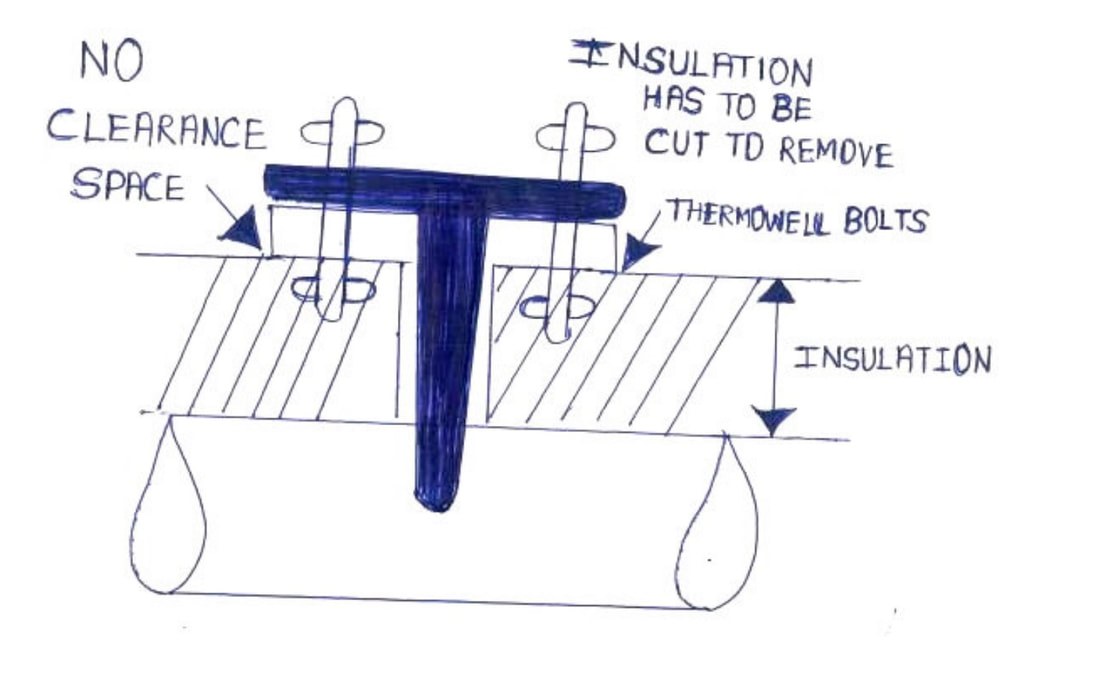

Not Recommended Pratice

It is a recommended and Good Engineering practice to have clearance of 100mm (4inches) between Insulation and the nozzle.

Why?

Because whenever we need to remove the Thermowell and if insulation is all the way up to the nozzle then we will have to cut the insulation to get to the Bolts, Which is not a good practice.

Refer the diagram provided above.

Let us take practical example

For Insulation between 0 to 50 mm we could have Standard standout of 150mm (6 Inch)

However when insulation is 100mm then standout must increase to 200mm (8 inches)

Thus, Clearance (100 mm) = Standout (200 mm) – Insulation Thickness (100 mm)

Further, if insulation is 150mm then standout must increase to 250mm (10 inches) so on and so forth.

So the Relation is as follows

Insulation (On pipe) affects Standout (Nozzle) which in turn affects U-length (Thermowell)

Hence we must cross verify at later stages that will standout get affected due to insulation !!

Accordingly ensure whether the thermowell tip actually is in contact with process as per our requirement !!

Hope this is helpful

PS : As always this is as per best of my current understanding !!

Why?

Because whenever we need to remove the Thermowell and if insulation is all the way up to the nozzle then we will have to cut the insulation to get to the Bolts, Which is not a good practice.

Refer the diagram provided above.

Let us take practical example

For Insulation between 0 to 50 mm we could have Standard standout of 150mm (6 Inch)

However when insulation is 100mm then standout must increase to 200mm (8 inches)

Thus, Clearance (100 mm) = Standout (200 mm) – Insulation Thickness (100 mm)

Further, if insulation is 150mm then standout must increase to 250mm (10 inches) so on and so forth.

So the Relation is as follows

Insulation (On pipe) affects Standout (Nozzle) which in turn affects U-length (Thermowell)

Hence we must cross verify at later stages that will standout get affected due to insulation !!

Accordingly ensure whether the thermowell tip actually is in contact with process as per our requirement !!

Hope this is helpful

PS : As always this is as per best of my current understanding !!

1000+ Downloads from engineers working in the likes of companies like Shell, Chevron, Dow, SABIC, Technip Energies, Worley, Emerson, ABB to name a few

"FREE E-Book on Engineering Standards"

Subscribe and grab your FREE E-book