RTJ flange interface problem with piping dept

A strange thing happened, Instrumentation department bought Orifice with RTJ ring (gasket) and Piping brought the RTJ Flanges.

Yet these both did not match !!!!

Why did this happen ?

Let’s figure it out together :-

First let’s see the types and then why it matters .

Well RTJ flanges are further divided into 3 types :- R type , RX type , BX type.

Normally the one we use in petrochemical industries is R- type RTJ flange and is used for 150 to 2500 pressure rating . so we don’t come across RX and BX type usually.

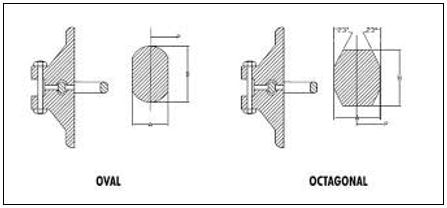

So now in R-type it is further divided into 2 type :- 1.Oval 2.Octagonal . (As per ASME B16.20)

Now when we mention in our datasheet RTJ flange . It is assumed we want R-type , Oval RTJ.

Here’s one case study for Orifice instruments.

The vendor provided RTJ type for orifice as we wanted ,But Here’s the catch !!

Sometimes vendor gives us RTJ octagonal type , Octagonal type because it has high sealing efficiency.

Note that the metal Ring /Gasket comes stuck to the orifice plate for RTJ type.

And usually the orifice plates are bought by instrumentation department and the flanges by piping.

And this type of RTJ (octagonal) is sometimes not highlighted in quote properly and it could be missed out by the one evaluating it.

So this could cause interface error as piping would assume oval type RTJ and we have bought Octagonal type.

Also Note,

There have been recent developments in RTJ flanges that interchangeability between type of gaskets/ring is possible (i.e it can accommodate either shape rings) , better consult with piping

before selection and what type of flange (oval, octagonal or interchangeable) are existing in the plant.

PS:- This is as per best of my current understanding.

Hope this has been of value to you !!

Here’s one case study for Orifice instruments.

The vendor provided RTJ type for orifice as we wanted ,But Here’s the catch !!

Sometimes vendor gives us RTJ octagonal type , Octagonal type because it has high sealing efficiency.

Note that the metal Ring /Gasket comes stuck to the orifice plate for RTJ type.

And usually the orifice plates are bought by instrumentation department and the flanges by piping.

And this type of RTJ (octagonal) is sometimes not highlighted in quote properly and it could be missed out by the one evaluating it.

So this could cause interface error as piping would assume oval type RTJ and we have bought Octagonal type.

Also Note,

There have been recent developments in RTJ flanges that interchangeability between type of gaskets/ring is possible (i.e it can accommodate either shape rings) , better consult with piping

before selection and what type of flange (oval, octagonal or interchangeable) are existing in the plant.

PS:- This is as per best of my current understanding.

Hope this has been of value to you !!