A guide on PIP International Standards naming system

PIP standards have an “Interesting” coding system when compared to other internationally recognized standards like API, ISO, ISA, ASME etc.

I am very weak at memorization but after understanding the concept behind the naming system, I can recall every PIP standard (57 standards for I&C engineers) without even memorizing a single letter.

After reading this article, you should be able to interpret all 57 active PIP standards (as of 26 May 2021) for Instrumentation engineers without even memorizing a single letter.

Note : This article is applicable to engineers from other disciplines as well.

However examples have been taken of standards that cater to Instrumentation and control discipline.

Without further delay let’s start with the article and by taking an example of ISO standard versus PIP standard for Flow meters

I am very weak at memorization but after understanding the concept behind the naming system, I can recall every PIP standard (57 standards for I&C engineers) without even memorizing a single letter.

After reading this article, you should be able to interpret all 57 active PIP standards (as of 26 May 2021) for Instrumentation engineers without even memorizing a single letter.

Note : This article is applicable to engineers from other disciplines as well.

However examples have been taken of standards that cater to Instrumentation and control discipline.

Without further delay let’s start with the article and by taking an example of ISO standard versus PIP standard for Flow meters

Example :

ISO standard for DP flow meter is ISO 5167

However, PIP standard for Flow meter’s Installation is named as PIP PCIFL100

Don’t you feel that these PIP standards have longer names and have higher complexity to remember as compared to conventional names of standard.

This is done for a specific reason, Let us explore this concept in detail

However, PIP standard for Flow meter’s Installation is named as PIP PCIFL100

Don’t you feel that these PIP standards have longer names and have higher complexity to remember as compared to conventional names of standard.

This is done for a specific reason, Let us explore this concept in detail

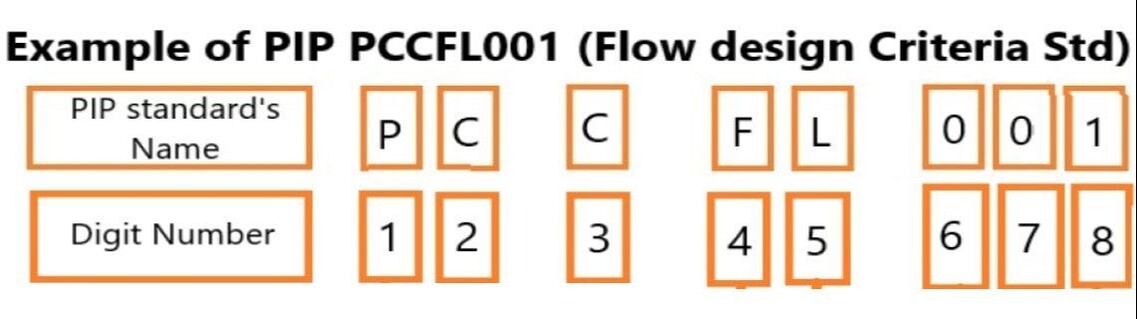

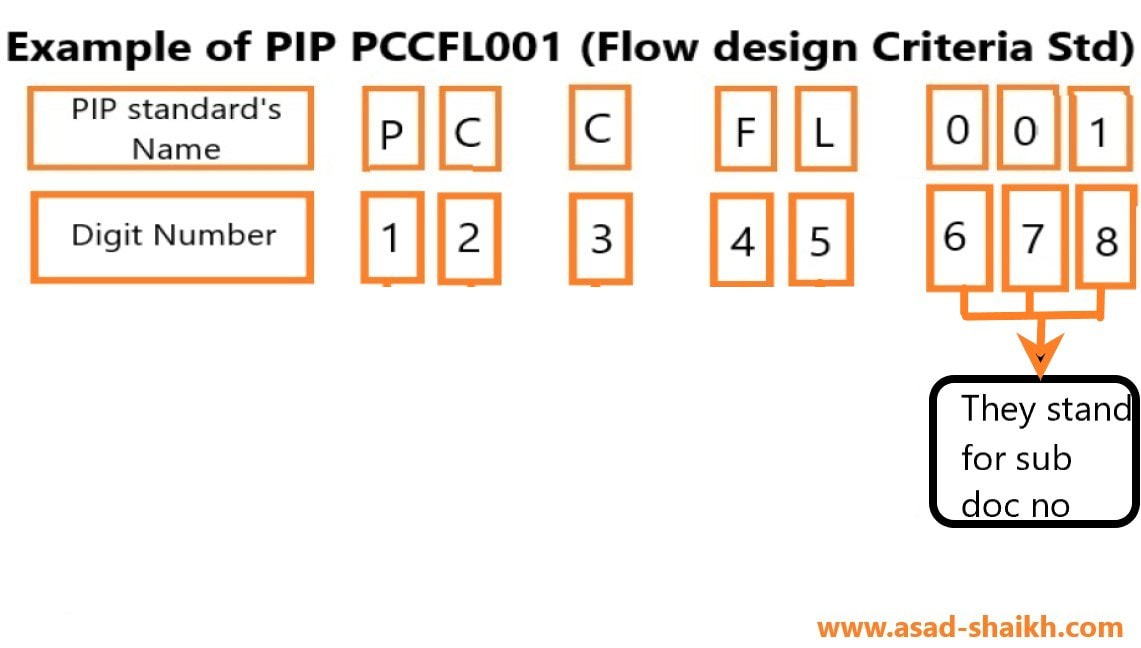

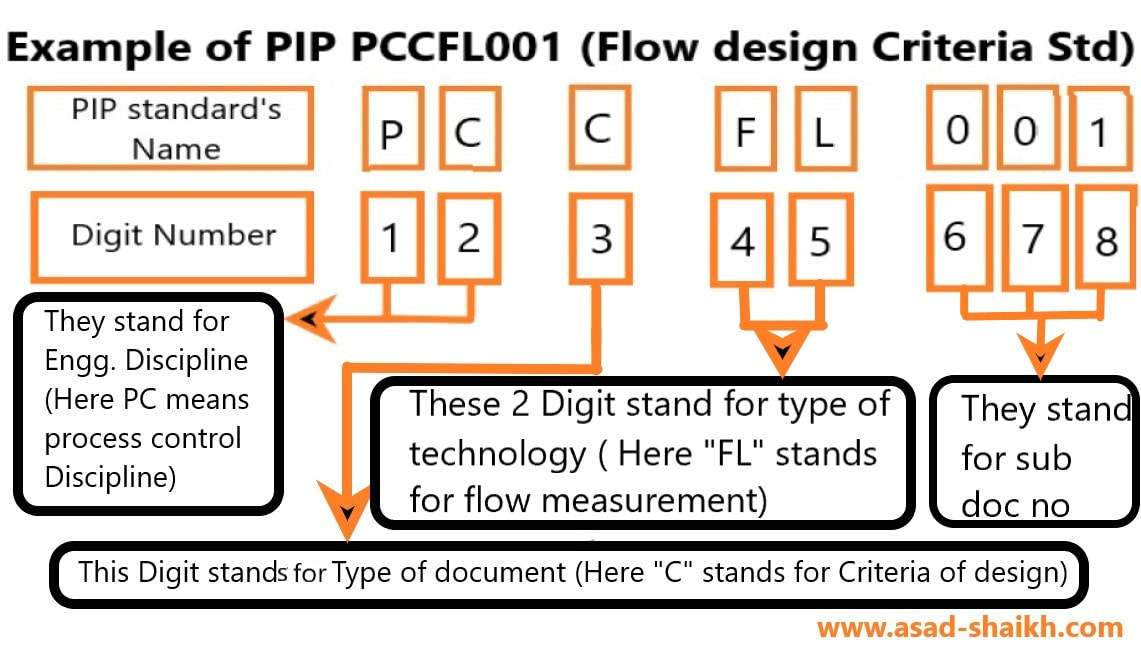

Breaking down PIP standards

Let us break down this standard’s name into individual digits and explore how this naming philosophy is developed.

Note that Every PIP instrumentation standard is divided into 8 Digits

Every digit has a significant role to play.

Example :

PIP standard for Flow meter’s criteria of design called PCCFL001

Here’s the breakdown of each digit

Note that Every PIP instrumentation standard is divided into 8 Digits

Every digit has a significant role to play.

Example :

PIP standard for Flow meter’s criteria of design called PCCFL001

Here’s the breakdown of each digit

Exploring the digits in depth

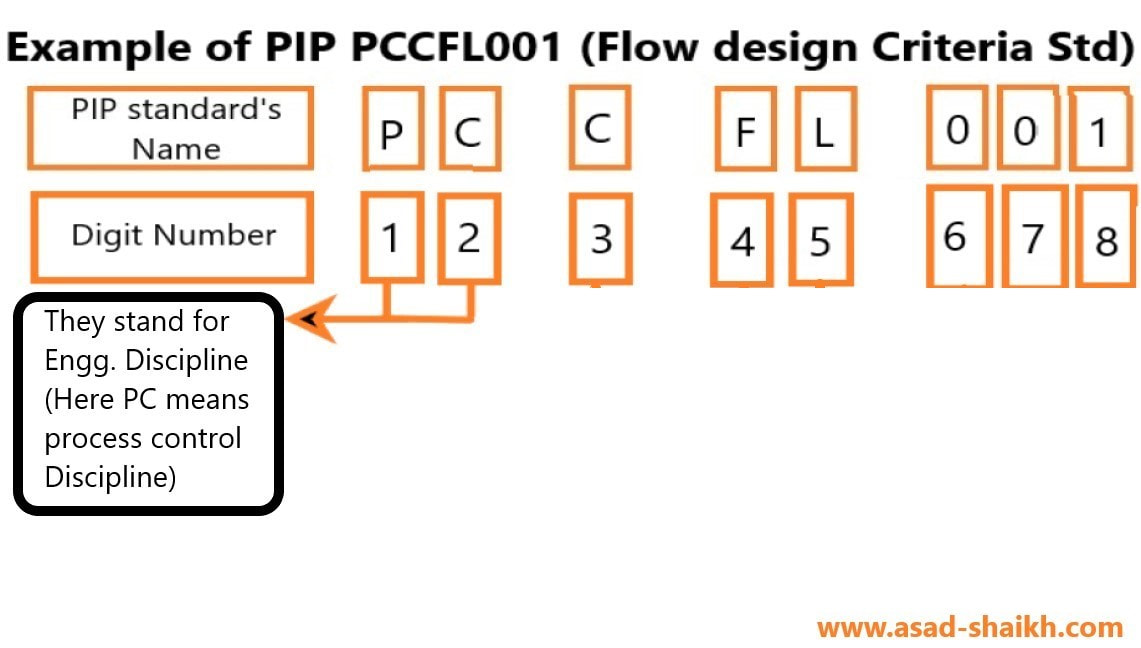

1.Digits 1 &2 stand for the Engineering discipline

This is the first criteria for segregating PIP standards as per applicable engineering discipline

Example –

1. PC :- stands for Process Control ( i.e Instrumentation and Control Engineering )

2.PN :- stands for Piping Engineering

3.EL :- stands for Electrical Engineering

Example –

1. PC :- stands for Process Control ( i.e Instrumentation and Control Engineering )

2.PN :- stands for Piping Engineering

3.EL :- stands for Electrical Engineering

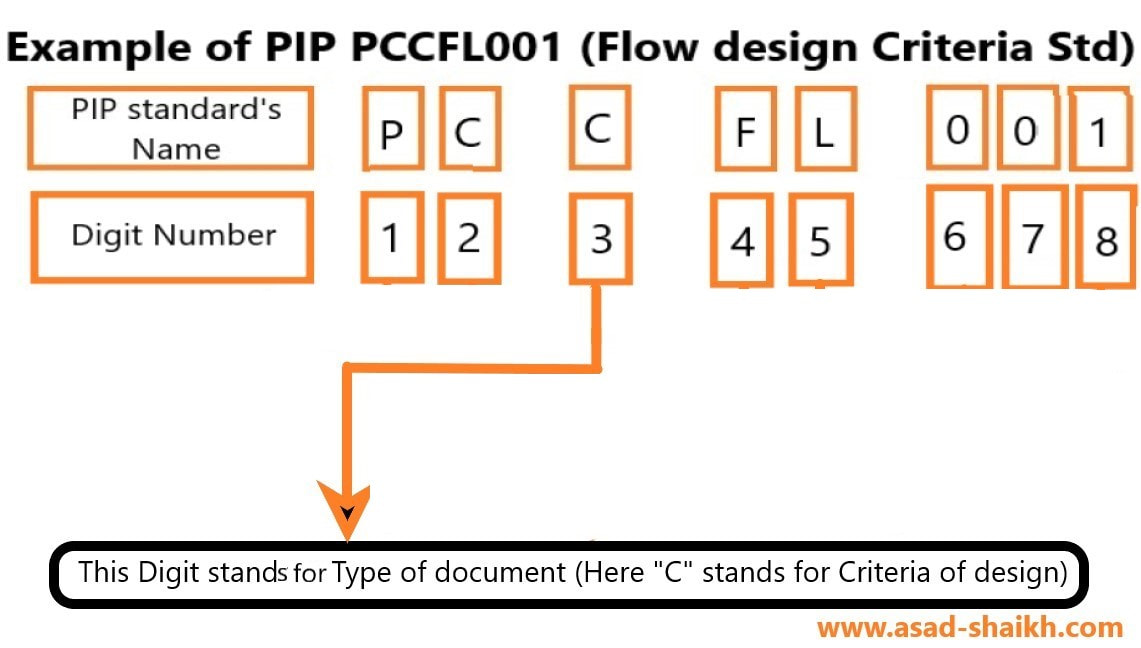

2.Digit 3 stands for type of document

Digit 3 classifies PIP standards as per their applicability in procurement cycle.*

1st stage of procurement cycle is selecting the right measurement technology.

Hence the third digit should be “E” which stands for Engineering Guide

Example 1 :

PCEFL001 is standard for flow meter engineering guide and thus the 3rd digit is “E”

2ND stage of procurement cycle logically seems to be specifying the instrument measurement technology selected above.

Hence the 3rd digit should be “C” that stands for Criteria of design (Design specification)

Example 2:

PCCFL001 is standard for flow meter criteria of design (Design specification) and thus the 3rd digit is “C”

Similarly the rest of the procurement cycle follows

“F” stands for Fabrication Details

“I” stands for Installation Details

“T” stands for Inspection and Testing Requirements

1st stage of procurement cycle is selecting the right measurement technology.

Hence the third digit should be “E” which stands for Engineering Guide

Example 1 :

PCEFL001 is standard for flow meter engineering guide and thus the 3rd digit is “E”

2ND stage of procurement cycle logically seems to be specifying the instrument measurement technology selected above.

Hence the 3rd digit should be “C” that stands for Criteria of design (Design specification)

Example 2:

PCCFL001 is standard for flow meter criteria of design (Design specification) and thus the 3rd digit is “C”

Similarly the rest of the procurement cycle follows

“F” stands for Fabrication Details

“I” stands for Installation Details

“T” stands for Inspection and Testing Requirements

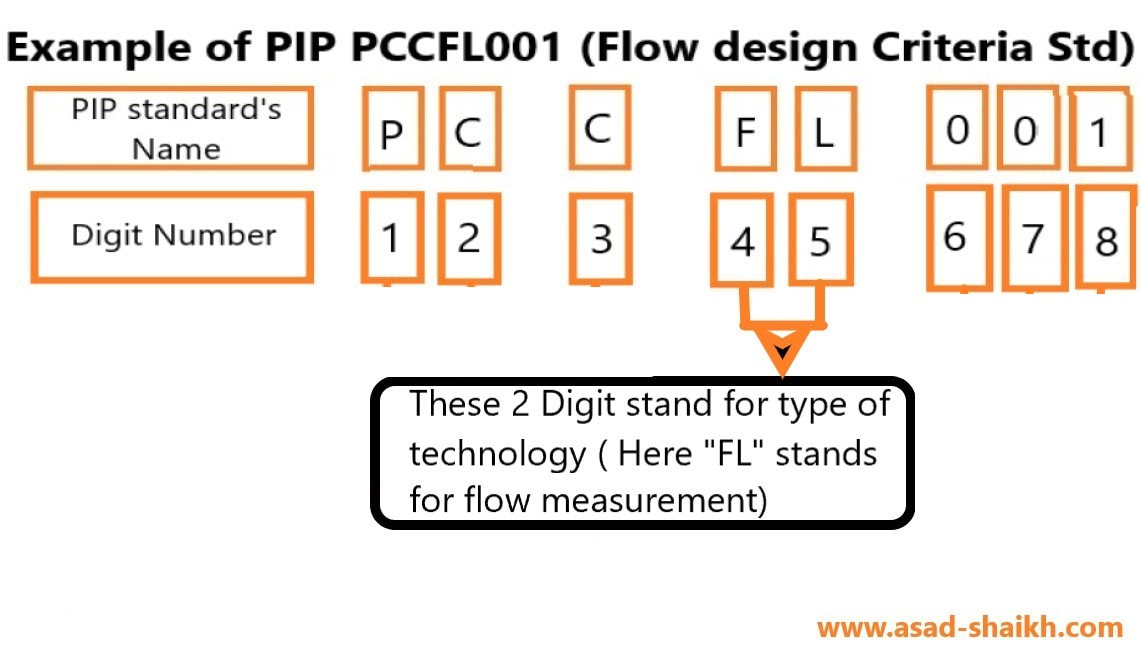

3.Digits 4 & 5 stand for type of technology

For level measurement the 4th & 5th are “LI”

Example :

PCILI100 is standard for Level Transmitter Installation Details.

Hence digits 4 & 5 in above example are “LI” which stand for level measurement

Similarly,

The digits 4 & 5 with the following alphabets are abbreviated as mentioned below

“TE” stands for Temperature measurement technology

“FL” stands for Flow measurement technology

“PR” stands for Pressure measurement technology

“CV” stands for control valve technology

Example :

PCILI100 is standard for Level Transmitter Installation Details.

Hence digits 4 & 5 in above example are “LI” which stand for level measurement

Similarly,

The digits 4 & 5 with the following alphabets are abbreviated as mentioned below

“TE” stands for Temperature measurement technology

“FL” stands for Flow measurement technology

“PR” stands for Pressure measurement technology

“CV” stands for control valve technology

4.Digits 6,7 & 8 stand’s for sub document numbering

PIP standard’s website has not defined these digits in great detail.

However, after a careful observation these seem to aid in identifying pages within the PIP standard

Example :

PCFTE100 is the standard for thermowell fabrication details

Within this standard there is subdivision on fabrication drawings of various thermowell types.

Hence these are separate within this standard as follows ( The last digit of this sub document number keeps changing )

PCFTE101 – Threaded Tapered Thermowell fabrication drawing

PCFTE102 – Flanged Tapered Thermowell fabrication drawing

PCFTE103 – Weld-in Tapered Thermowell fabrication drawing

PCFTE104 – Socketweld Tapered Thermowell fabrication drawing

However, after a careful observation these seem to aid in identifying pages within the PIP standard

Example :

PCFTE100 is the standard for thermowell fabrication details

Within this standard there is subdivision on fabrication drawings of various thermowell types.

Hence these are separate within this standard as follows ( The last digit of this sub document number keeps changing )

PCFTE101 – Threaded Tapered Thermowell fabrication drawing

PCFTE102 – Flanged Tapered Thermowell fabrication drawing

PCFTE103 – Weld-in Tapered Thermowell fabrication drawing

PCFTE104 – Socketweld Tapered Thermowell fabrication drawing

Conclusion

Let us summarize the entire coding system below

Hope you have found this article valuable and interesting.

This is as per best of my current understand. Feel free to share your thoughts with me via “contact me” page on www.asad-shaikh.com

This is as per best of my current understand. Feel free to share your thoughts with me via “contact me” page on www.asad-shaikh.com

A small Gift

Here’s a free E-book on diaphragm seal systems that you might find useful and interesting and the best part is that these lessons can be applied to almost any instrument that we are responsible to design and engineer.

I am really humbled and glad that engineers from 150+ companies including the likes of ADNOC, SABIC, DOW chemicals, Bechtel, Fluor, Worley, Technip, Emerson, ABB, Yokogawa etc have found it valuable and interesting.

I hope that this book adds value to your knowledge base and engineering acumen.

Here’s a free E-book on diaphragm seal systems that you might find useful and interesting and the best part is that these lessons can be applied to almost any instrument that we are responsible to design and engineer.

I am really humbled and glad that engineers from 150+ companies including the likes of ADNOC, SABIC, DOW chemicals, Bechtel, Fluor, Worley, Technip, Emerson, ABB, Yokogawa etc have found it valuable and interesting.

I hope that this book adds value to your knowledge base and engineering acumen.