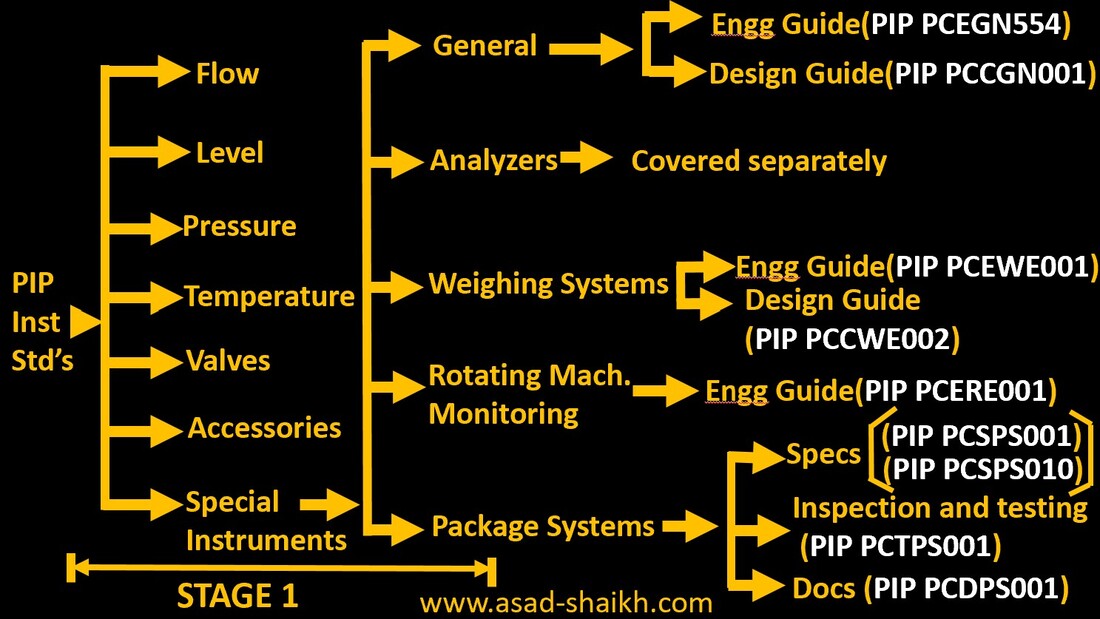

Instrumentation PIP Standard’s Summary

PIP standards are international recognized standards for process industries and are adapted by world renowned companies in the energy and chemical market.

The members include companies like Shell, BASF, SABIC, Worley, Jacobs, and Bayer to name a few.

Why are these standards so widely used?

These standards are very simple to comprehend.

They are short and to the point.

They are easy to implement.

Do you know the total number of PIP standards that are applicable to Instrumentation & Control discipline?

There are 57 active PIP standards that cater to the needs of Instrumentation and control discipline (as of March 2021)

Intimidating Numbers?

57 standards might seem intimidating at first and it would seem confusing where to start!

When I first came across these standards even, I felt the same!

Sharing my personal Notes

In order to track and learn these standards I had made some personal notes.

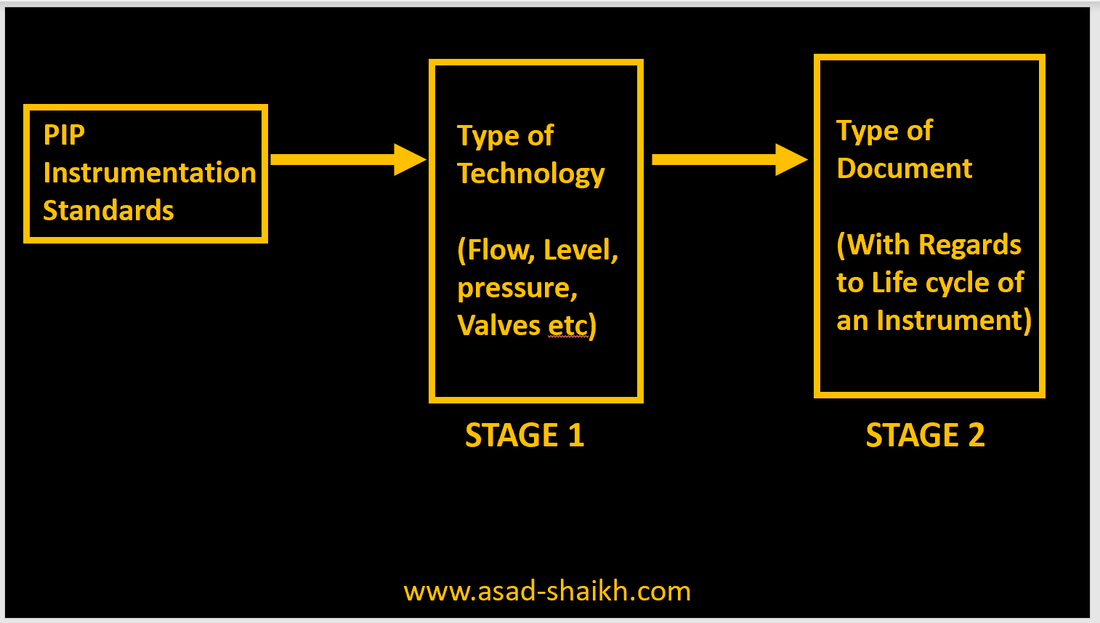

In these notes I have divided the standards into two stages so that it becomes easy and handy to understand the applicability of these standards.

The below is a segregation of PIP standards in these 2 stages

After learning this you can develop your own technique to classify these standards as per your taste and preference!!

Note: This is based on my personal notes to keep track of these standards; The official PIP website does not divide these standards into stage 1 or stage 2.

Basic Segregation of these PIP Instrumentation standards

Stage 1: Deals with the Type of technology

Stage 2: Deals with the Type of procurement/ life cycle that the instrument is in (or in other words it can be termed as Type of Document)

Stage 2: Deals with the Type of procurement/ life cycle that the instrument is in (or in other words it can be termed as Type of Document)

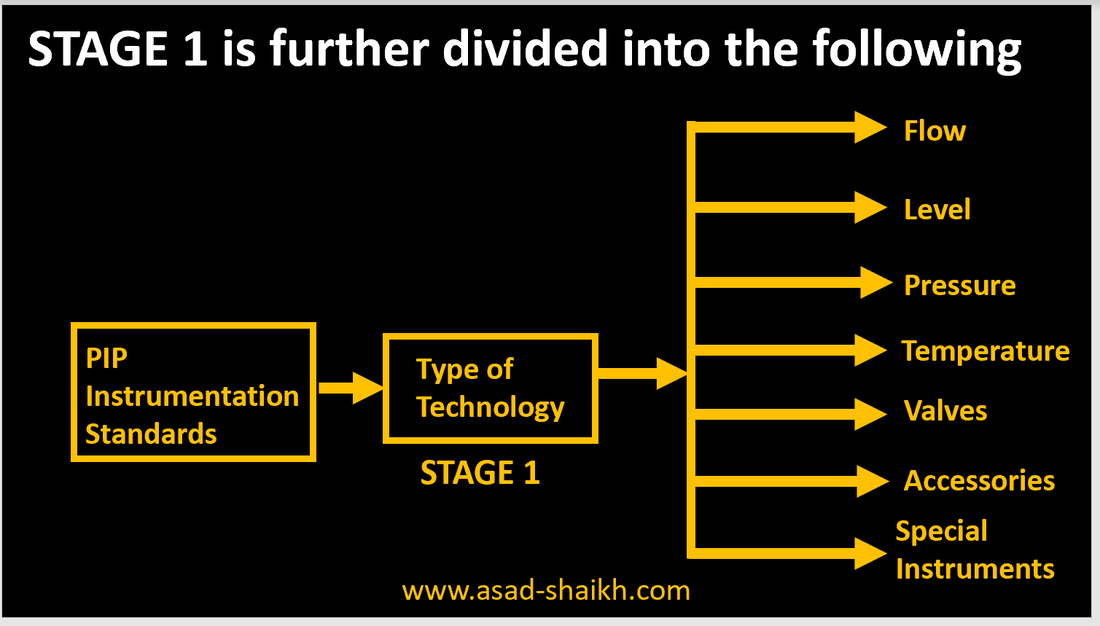

Let’s explore Stage 1 in detail

I have tried to divided stage 1 into 7 types

These are usually the major types that we I&C engineers come across.

i.e. Flow, Pressure, Temperature, Level, Valves, Accessories and Special Instruments

Special instruments include analyzers, weight measurement instruments etc. which we will discuss further towards the end

These are usually the major types that we I&C engineers come across.

i.e. Flow, Pressure, Temperature, Level, Valves, Accessories and Special Instruments

Special instruments include analyzers, weight measurement instruments etc. which we will discuss further towards the end

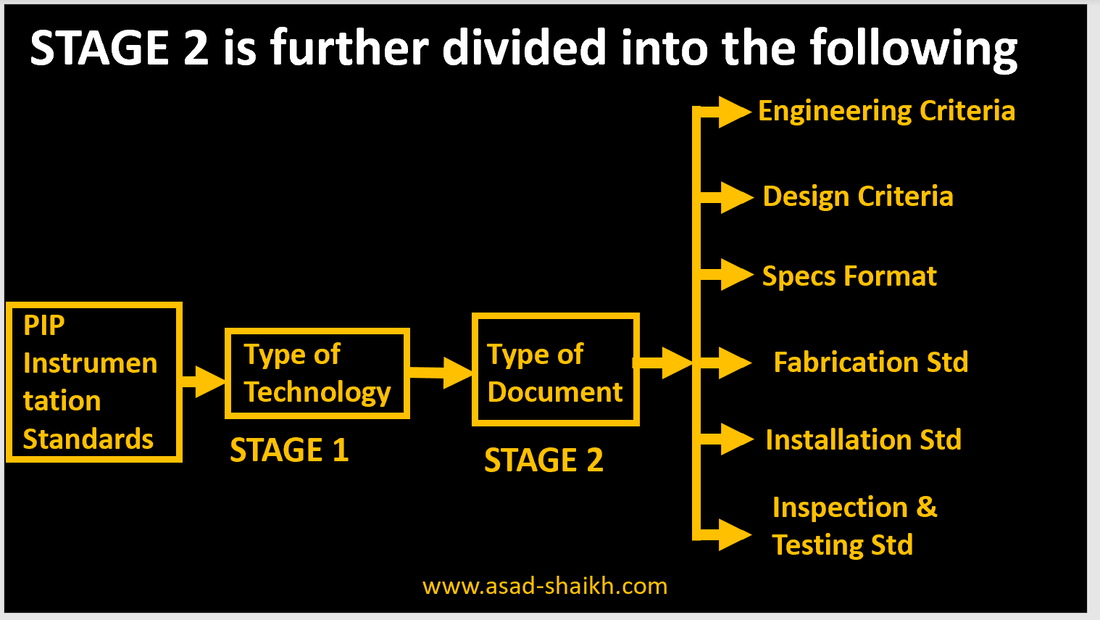

Let’s explore Stage 2 in detail

Stage 2 is divided into 6 types

Stage 2 is an enhanced segregation of Instrument types covered in Stage 1

These types are a logical sequence for engineering any technology.

Stage 2 is an enhanced segregation of Instrument types covered in Stage 1

These types are a logical sequence for engineering any technology.

- Engineering criteria facilitates the selection of type of Instrument (i.e. whether we should use orifice or Coriolis for flow technology)

- Design criteria facilitates the requirement to design the Instrument (i.e. whether what details are required for orifice meters like beta ratio limit, turndown etc.)

- Specs facilitates the framework/format for preparing a datasheet

- Fabrication Standard facilitates the requirement for fabrication of the instrument (i.e. what should be the taper ratio of Thermowell etc.)

- Installation standard as the name suggest facilitates the procedure and the hookup required to install an Instrument on the field (i.e. the DP transmitter are to be required to be installed below the piping for Liquid service)

- Inspection and testing as the name suggest specifies the requirements for Inspection and testing requirements of Instrumentation.

Note: Not all these 6 types don’t apply to every Instrument technology.

Example of Fabrication Standard

For Radar or other Level instruments, fabrication standard is not mentioned since most of the details are vendor specific and very less details are required to be specified for its construction.

However, For Thermowell or Orifice plates, fabrication standard is provided since it has a lot of details that need to be specified to the vendor.

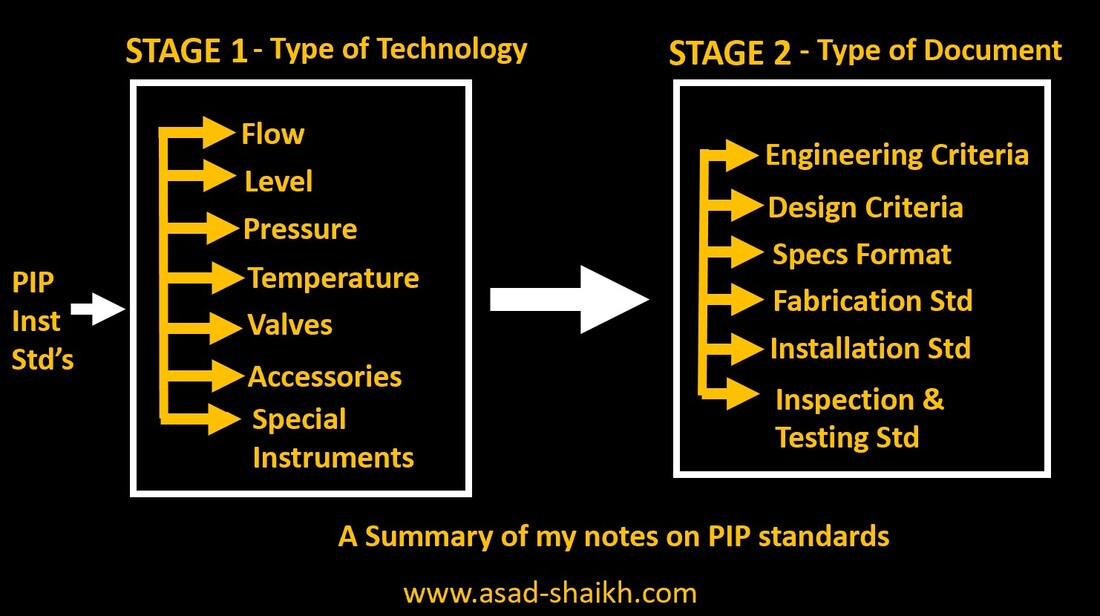

let's combine Stage 1 & 2

We would be now combining this combination of stage 1 and stage 2 and create combinations for various Instrumentation technologies

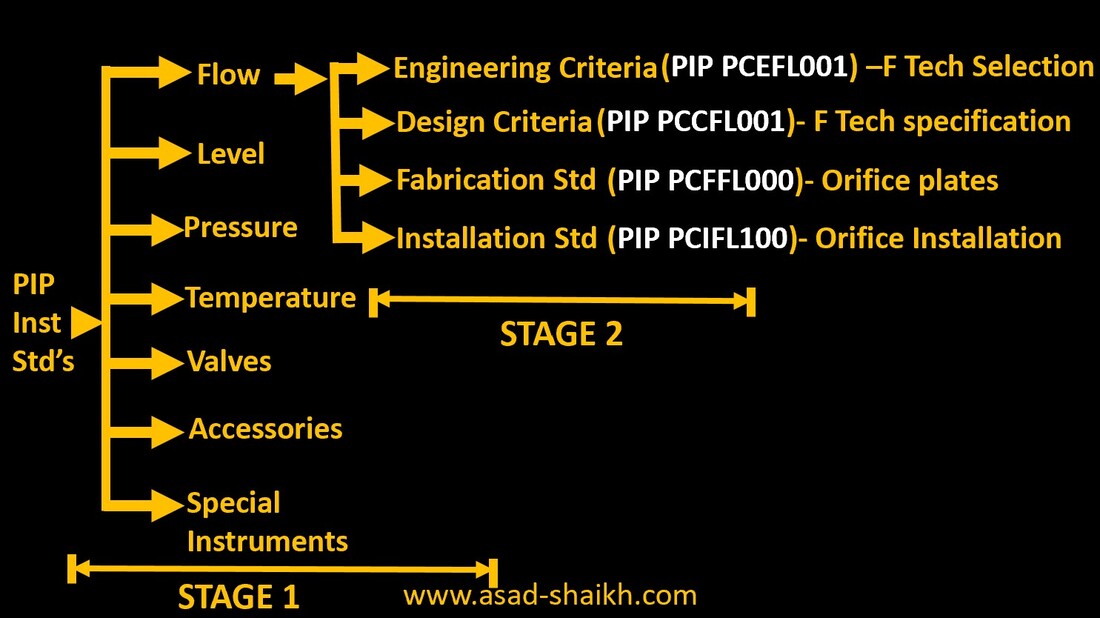

PIP Standards for Flow Technology

We would be starting with Flow Technology.

There are 4 PIP standards that cater to the needs of Flow measurement technology

The Name of the standard is highlighted in white and a brief description is highlighted in yellow.

There are 4 PIP standards that cater to the needs of Flow measurement technology

The Name of the standard is highlighted in white and a brief description is highlighted in yellow.

Understanding Flow Technology standards

As we had previously discussed the standards are aligned in a logical sequence.

1. Engineering standard

The Engineering standard PCEFL001 helps us to understand which flow meter technology would be suitable for our application.

2. Design criteria

One this gets finalized then the design criteria would help us to define what needs to be specified to design the instrument for our application.

3. Fabrication of Orifice plate

Orifice plates require a lot of details for fabrication like plate thickness, Bore diameter etc.

Hence a standard for fabrication of orifice plate is created to cater to this need called as PIP PCCFL001

4. Installation Requirements

Finally, we know that for orifice flow transmitter installation there are certain requirements like installing the transmitter below tapings for Liquid service and above tapping for steam service and thus we have a dedicated standard PIP PCIFL100 that defines the installation requirements.

Similarly, all the other technologies listed below follow a similar pattern.

1. Engineering standard

The Engineering standard PCEFL001 helps us to understand which flow meter technology would be suitable for our application.

2. Design criteria

One this gets finalized then the design criteria would help us to define what needs to be specified to design the instrument for our application.

3. Fabrication of Orifice plate

Orifice plates require a lot of details for fabrication like plate thickness, Bore diameter etc.

Hence a standard for fabrication of orifice plate is created to cater to this need called as PIP PCCFL001

4. Installation Requirements

Finally, we know that for orifice flow transmitter installation there are certain requirements like installing the transmitter below tapings for Liquid service and above tapping for steam service and thus we have a dedicated standard PIP PCIFL100 that defines the installation requirements.

Similarly, all the other technologies listed below follow a similar pattern.

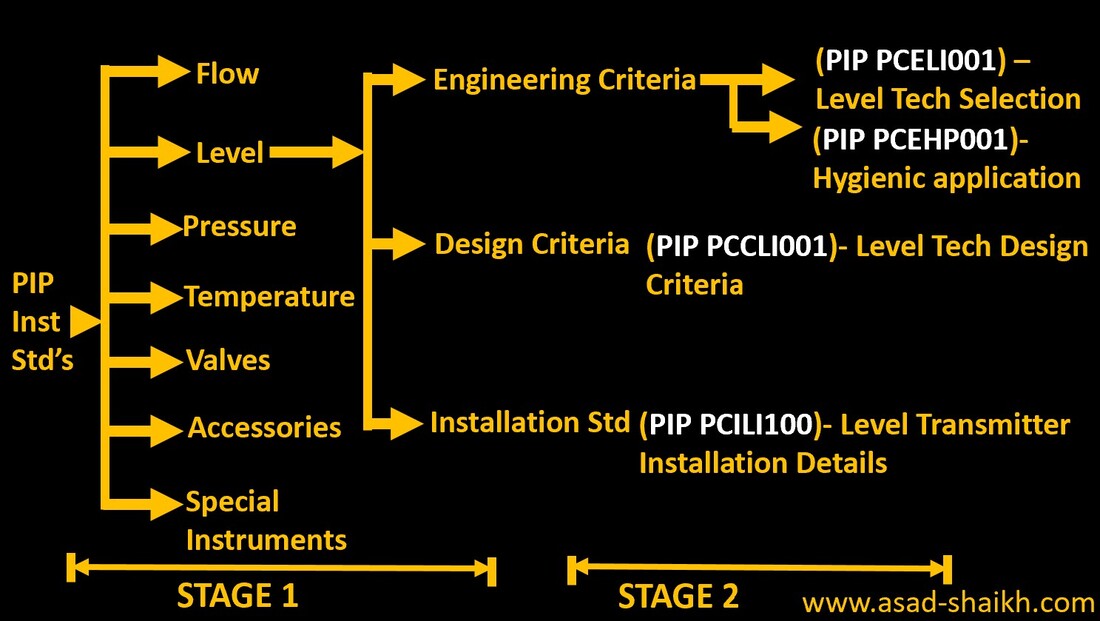

PIP Standards for Level Technology

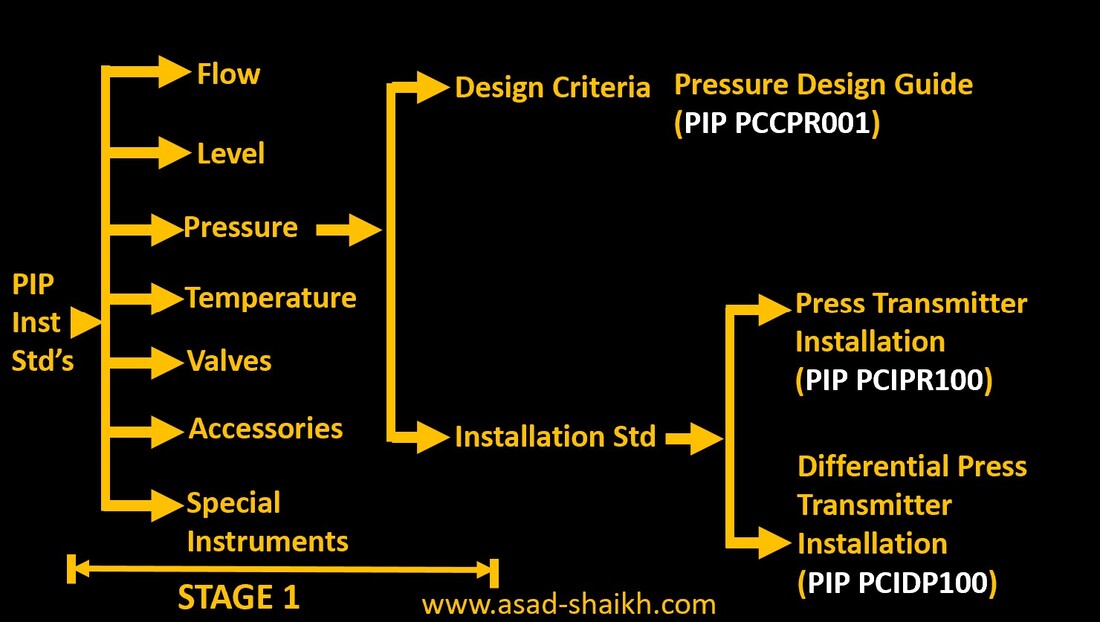

PIP Standards for Pressure Technology

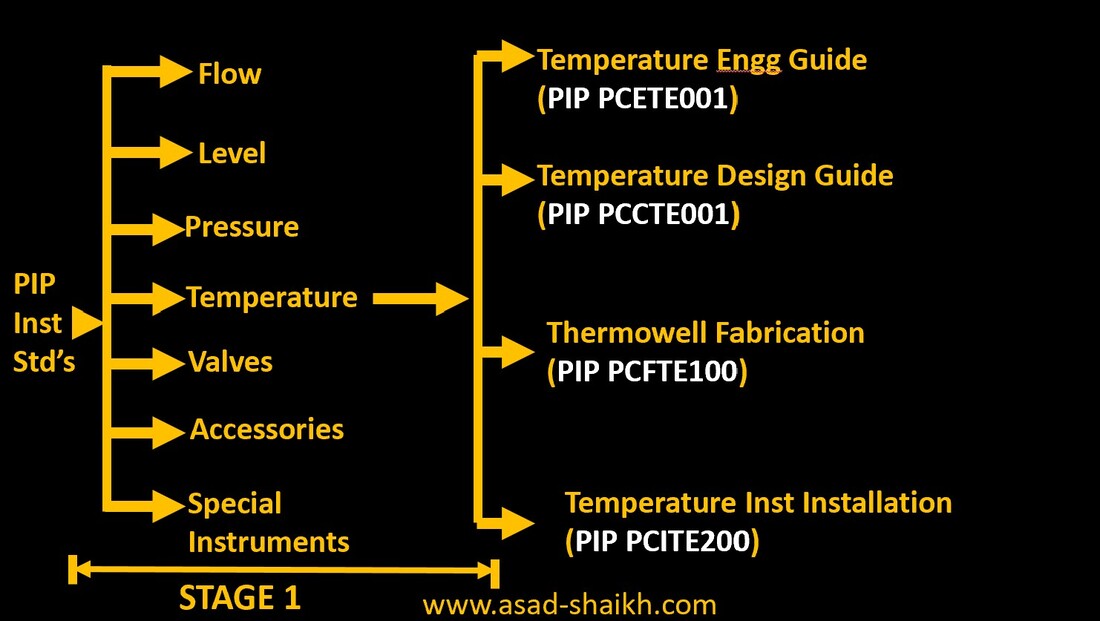

PIP Standards for Temperature Technology

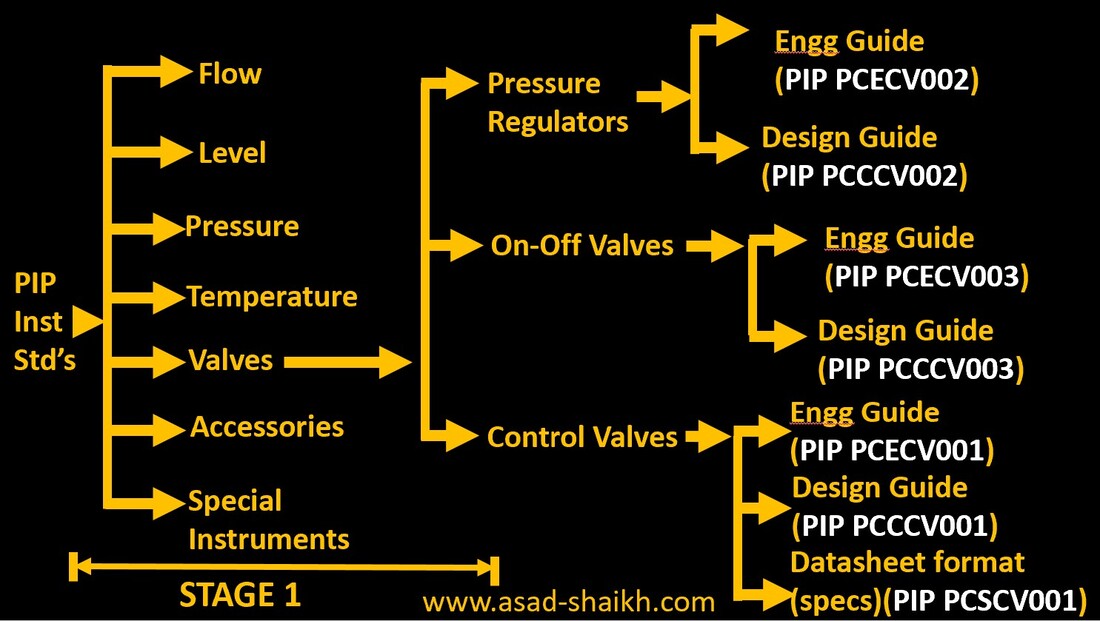

PIP Standards for Valves

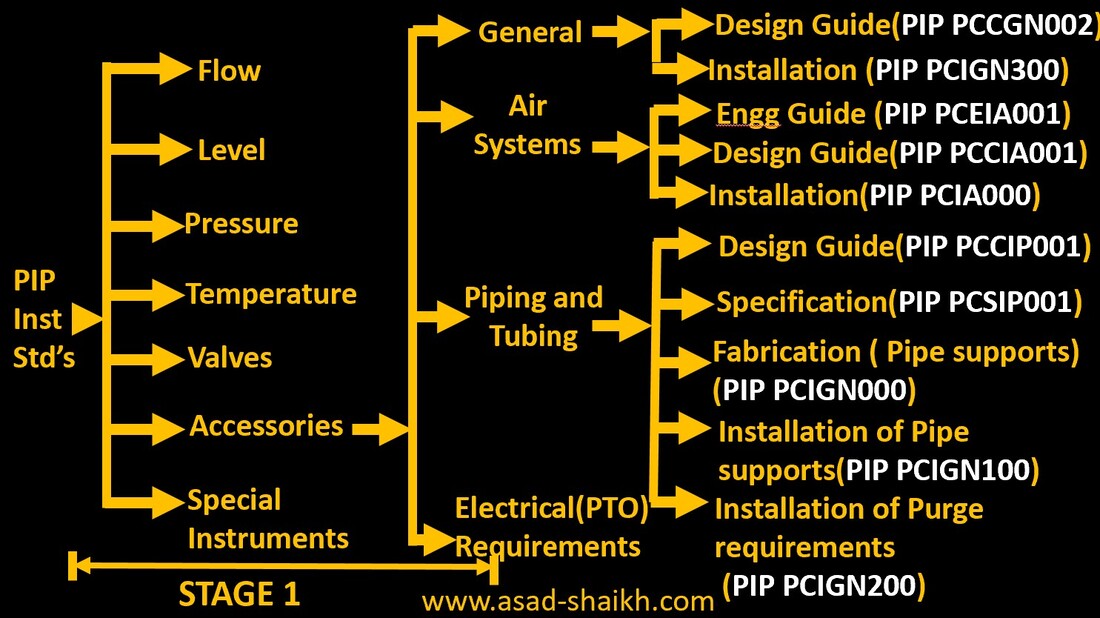

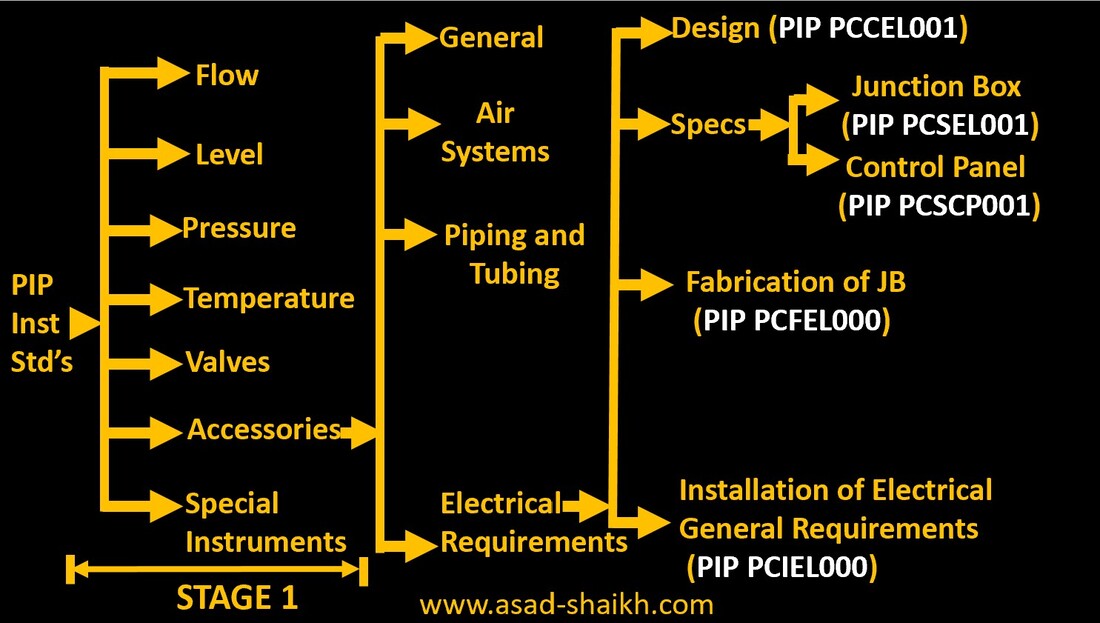

PIP Standards for Instrument accessories

(Part-1)

PIP Standards for Instrument accessories

(Part-2)

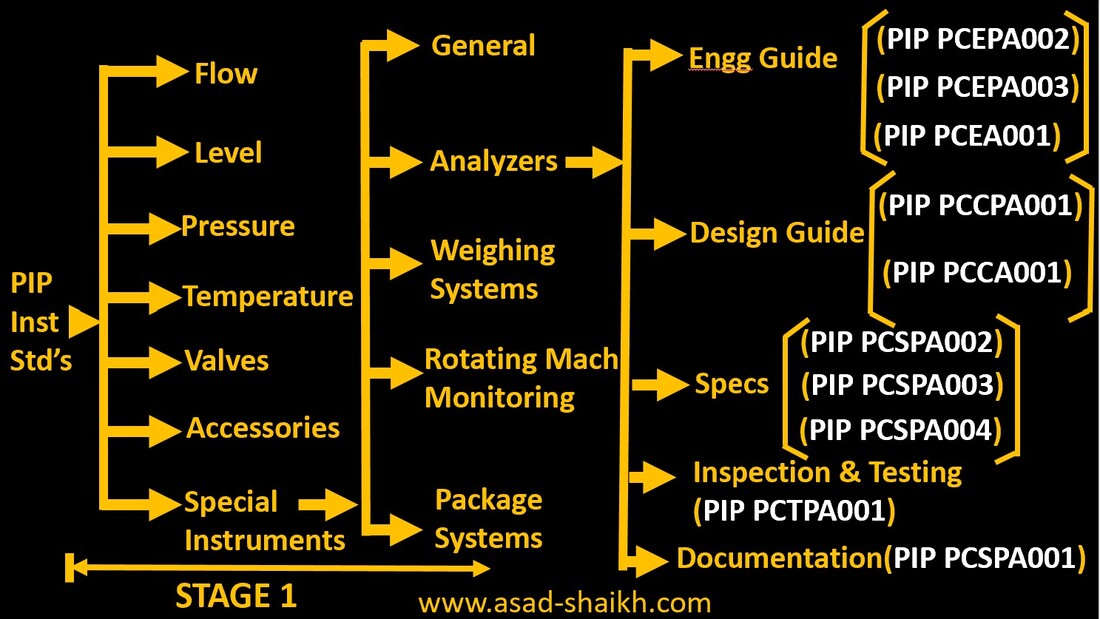

PIP Standards for Analyzers

PIP Standards for Special Instruments

Conclusion

Thus, we can conclude the summary of my notes on PIP standards.

These standards are initially segregated as per type of technology and is termed as Stage 1

Then these technologies are further divided as per their applicability on the life of the instrument termed as stage 2.

Hope you have found my notes on PIP standards useful.

And you can take this further and develop into a segregation style that meets your taste!!

These standards are initially segregated as per type of technology and is termed as Stage 1

Then these technologies are further divided as per their applicability on the life of the instrument termed as stage 2.

Hope you have found my notes on PIP standards useful.

And you can take this further and develop into a segregation style that meets your taste!!

Is this Free E-book really important?

We as engineers have tremendous responsibility when it comes to engineering.

We must be well grounded in the fundamental concepts of engineering.

The below E-book covers concepts of Erosion, Gasket selection, Fill fluid vaporization, gold plating ,full vacuum protection etc.

I am really humbled and glad that engineers from 150+ companies including the likes of ADNOC, SABIC, DOW chemicals, Bechtel, Fluor, Worley, Technip, Emerson, ABB, Yokogawa etc have found it valuable and interesting.

I hope you would find the E-book valuable and interesting.

We as engineers have tremendous responsibility when it comes to engineering.

We must be well grounded in the fundamental concepts of engineering.

The below E-book covers concepts of Erosion, Gasket selection, Fill fluid vaporization, gold plating ,full vacuum protection etc.

I am really humbled and glad that engineers from 150+ companies including the likes of ADNOC, SABIC, DOW chemicals, Bechtel, Fluor, Worley, Technip, Emerson, ABB, Yokogawa etc have found it valuable and interesting.

I hope you would find the E-book valuable and interesting.