We Know in Mag flow meters we must check conductivity of Fluid

Mag flow meters are made of Liner material (PTFE , ETFE etc) so why to check corrosion rate ?

Firstly If we are working on a project from where to know the Corrosion / Erosion rate ?

Corrosion / Erosion rate of a process fluid is usually provided in Piping material specifications (PMS) in rare cases if absent consult with material engineer.

The Exact counter to Corrosion is Corrosion Allowance.

Mag flow meters are made of Liner material (PTFE , ETFE etc) so why to check corrosion rate ?

Firstly If we are working on a project from where to know the Corrosion / Erosion rate ?

Corrosion / Erosion rate of a process fluid is usually provided in Piping material specifications (PMS) in rare cases if absent consult with material engineer.

The Exact counter to Corrosion is Corrosion Allowance.

Basics of Corrosion Allowance

So let’s take a hypothetical Example:-

if a Pipe corrodes at a Rate of 0.02 inches per year you will provide corrosion allowance of maybe a 0.5 inch

That means if in one year the Pipe gets corroded 0.02 inches then in 25 Years it will get corroded upto 0.5 inches

Corrosion in Mag Flow Meter

Well there is one important but small part in mag flow meter that gets affected with corrosion / Erosion rate :-“The Electrodes “

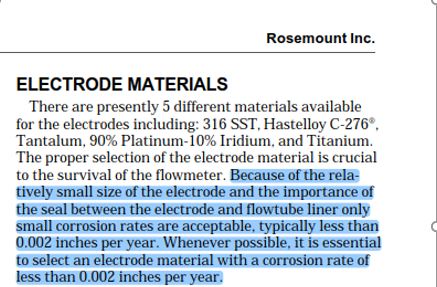

Because of the relatively small size of the electrode and the importance of the seal between the electrode and flow tube liner only small corrosion rates are acceptable, typically less than 0.002 inches per year.

Refer The Snippet from Technical Datasheet :-TDS 3033

if a Pipe corrodes at a Rate of 0.02 inches per year you will provide corrosion allowance of maybe a 0.5 inch

That means if in one year the Pipe gets corroded 0.02 inches then in 25 Years it will get corroded upto 0.5 inches

Corrosion in Mag Flow Meter

Well there is one important but small part in mag flow meter that gets affected with corrosion / Erosion rate :-“The Electrodes “

Because of the relatively small size of the electrode and the importance of the seal between the electrode and flow tube liner only small corrosion rates are acceptable, typically less than 0.002 inches per year.

Refer The Snippet from Technical Datasheet :-TDS 3033

A common Question:- I have not checked corrosion rate while procuring mag flow meter but still it worked ?

Answer :- This so because usually Pipe material is carbon steel and we instrumentation dept. take SS316 as our choice on carbon steel pipe and since Stainless steel is far more corrosion resistant than Carbon steel we don’t check corrosion rate.

But when pipe material is stainless steel or higher this becomes a significant consideration.

Especially if we are also selecting the same material as that of the pipe ,we must verify the corrosion rate.

I have come across pipe with corrosion /erosion rate as high as 0.125 inches / year for Duplex 2205 pipes.

Thanks for Reading !!

I hope its been of value to you.

if you would like to receive a new technical article every alternate Friday add you email ID to the Newsletter Below

PS: This is as per best of my current understanding.

Answer :- This so because usually Pipe material is carbon steel and we instrumentation dept. take SS316 as our choice on carbon steel pipe and since Stainless steel is far more corrosion resistant than Carbon steel we don’t check corrosion rate.

But when pipe material is stainless steel or higher this becomes a significant consideration.

Especially if we are also selecting the same material as that of the pipe ,we must verify the corrosion rate.

I have come across pipe with corrosion /erosion rate as high as 0.125 inches / year for Duplex 2205 pipes.

Thanks for Reading !!

I hope its been of value to you.

if you would like to receive a new technical article every alternate Friday add you email ID to the Newsletter Below

PS: This is as per best of my current understanding.

Reference :-Rosemount Technical Data Sheet TDS 3033