Installation Concerns for Diaphragm seals

Imagine buying a Ferrari and having no place to park?

The same story happens with diaphragm seal systems as well.

A lot of time is spend on selecting the correct diaphragm seal, however very less consideration is given on the design aspect.

Thus your amazing diaphragm seal like the Ferrari is procured on site but has installation flaw that dramatically reduce the functionality of diaphragm seals.

The same story happens with diaphragm seal systems as well.

A lot of time is spend on selecting the correct diaphragm seal, however very less consideration is given on the design aspect.

Thus your amazing diaphragm seal like the Ferrari is procured on site but has installation flaw that dramatically reduce the functionality of diaphragm seals.

Space consideration for bending radius of capillary

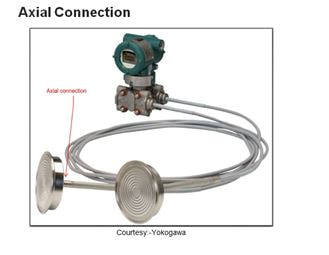

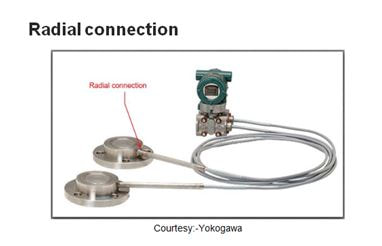

The capillary connecting to the diaphragm seal would require clearance in the X-Y or Y-Z plane depending on its connection to diaphragm flange (Axial or radial)

As a rule of thumb the bending radius of 150mm should be provided.

For axial connection (flange mounted on horizontal surface) it should be provided in vertical plane and for radial it should be provided in horizontal plane.

This is critical when there is a cluster of pipes in close proximity and a diaphragm seal has to be tapped into one those pipes.

As a rule of thumb the bending radius of 150mm should be provided.

For axial connection (flange mounted on horizontal surface) it should be provided in vertical plane and for radial it should be provided in horizontal plane.

This is critical when there is a cluster of pipes in close proximity and a diaphragm seal has to be tapped into one those pipes.

Armored Capillary :-

The Capillary tubes are sensitive and hence it is prefer to have them armored.

The most widely used choice of material selection is SS316 Armored.

Sometimes, PVC coated capillaries are also used. However for such cases it must be known that PCV has temperature limitation and the fill fluid must not get heated beyond PVC’s sustainable temperature else it would melt.

Calculation of capillary length:-

It is advisable to have a safety margin while calculating the length of capillary due to the following reasons.

1. Capillaries are hard and require a bending radius of approximately 150mm.

2. Site conditions would require a different path of capillary connection between transmitter and diaphragm seal than the one estimated in design phase.

(Safe practice is to consider longest path between diaphragm seal and transmitter the extra length of capillary can be coiled up)

Contents

3. If the length of capillary falls short on site then it is not possible to add an extra meter of length, a new assembly would be required.

Extra Capillary length

It is advisable to coil the extra capillary and not let it run lose causing people to trip or cause errors.

Strut connections on Vessel

This is a important consideration that gets overlooked.

The Diaphragm seal assembly is also used for level measurement and we know the distance between the two tapping of DP LT measurement could be large.

For such long distances the capillary cannot be hanging in air, The Clients who are very particular in safety aspect usually have it mentioned in their design basis that such capillary should run via a 50 mm tray across the vessel.

The real concern is that in order to mount the 50 mm tray we need strut support on the vessel.

Note that after the equipment is fabricated and shipped to site it is usually not allowed to drill anything on the equipment since it could affect the integrity of the equipment.(sometimes such drilling requires lot of approvals and are often referred to as hot permission)

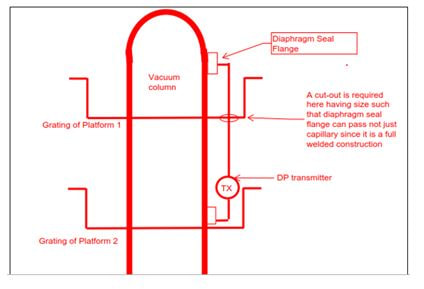

Cut out between platform

When we mount diaphragm seal on a tank there is high probability that we need provide cut out between gratings on various platforms.

These cut out size are sometimes mistaken by design team and the cutout length of capillary are considered.

However diaphragm seal capillary tubes are usually full welded to Diaphragm flange on one end and transmitter on the other end.

Hence the cutout must be given between grating/Platform keeping Diaphragm seal flange’s length in mind.

(Refer following diagram indicating a typical case)

The Capillary tubes are sensitive and hence it is prefer to have them armored.

The most widely used choice of material selection is SS316 Armored.

Sometimes, PVC coated capillaries are also used. However for such cases it must be known that PCV has temperature limitation and the fill fluid must not get heated beyond PVC’s sustainable temperature else it would melt.

Calculation of capillary length:-

It is advisable to have a safety margin while calculating the length of capillary due to the following reasons.

1. Capillaries are hard and require a bending radius of approximately 150mm.

2. Site conditions would require a different path of capillary connection between transmitter and diaphragm seal than the one estimated in design phase.

(Safe practice is to consider longest path between diaphragm seal and transmitter the extra length of capillary can be coiled up)

Contents

3. If the length of capillary falls short on site then it is not possible to add an extra meter of length, a new assembly would be required.

Extra Capillary length

It is advisable to coil the extra capillary and not let it run lose causing people to trip or cause errors.

Strut connections on Vessel

This is a important consideration that gets overlooked.

The Diaphragm seal assembly is also used for level measurement and we know the distance between the two tapping of DP LT measurement could be large.

For such long distances the capillary cannot be hanging in air, The Clients who are very particular in safety aspect usually have it mentioned in their design basis that such capillary should run via a 50 mm tray across the vessel.

The real concern is that in order to mount the 50 mm tray we need strut support on the vessel.

Note that after the equipment is fabricated and shipped to site it is usually not allowed to drill anything on the equipment since it could affect the integrity of the equipment.(sometimes such drilling requires lot of approvals and are often referred to as hot permission)

Cut out between platform

When we mount diaphragm seal on a tank there is high probability that we need provide cut out between gratings on various platforms.

These cut out size are sometimes mistaken by design team and the cutout length of capillary are considered.

However diaphragm seal capillary tubes are usually full welded to Diaphragm flange on one end and transmitter on the other end.

Hence the cutout must be given between grating/Platform keeping Diaphragm seal flange’s length in mind.

(Refer following diagram indicating a typical case)

Venting of Flushing ring or flushing flange ports

Diaphragm seal are usually used when the tradition differential pressure transmitter with Impulse lines cannot be used. Usually these services are Toxic, Corrosive, erosive or highly viscous.

The flushing ring/flange as discussed in previous chapter are used to periodically clean the diaphragm seal membrane. For certain toxic services it is a mandatory requirement that the residue after cleaning the diaphragm seal membrane should not be let out in the atmosphere rather it must be collected.

So for such cases an impulse tube is connected to the outlet of flushing ring which further connects to common collection sump. If this is the case then the Impulse tube, Connectors must be identified and procured accordingly and must be indicated or mentioned in installation drawing of the same.

Diaphragm seal are usually used when the tradition differential pressure transmitter with Impulse lines cannot be used. Usually these services are Toxic, Corrosive, erosive or highly viscous.

The flushing ring/flange as discussed in previous chapter are used to periodically clean the diaphragm seal membrane. For certain toxic services it is a mandatory requirement that the residue after cleaning the diaphragm seal membrane should not be let out in the atmosphere rather it must be collected.

So for such cases an impulse tube is connected to the outlet of flushing ring which further connects to common collection sump. If this is the case then the Impulse tube, Connectors must be identified and procured accordingly and must be indicated or mentioned in installation drawing of the same.

Hope you found it valuable.

Thanks for Reading.

This article is an excerpt from my free E-book "Engineering diaphragm seals for the industrial world"

Thanks for Reading.

This article is an excerpt from my free E-book "Engineering diaphragm seals for the industrial world"