Concept of Pressure measurement through Gas (N2) purging

First thing , the pressure never gets transferred from the process side to transmitter when gases are used for purging as gases are mostly compressible in nature .

Basics of Purging will get clear in this introduction (*1) and then the Analogy with Weighing scale (force balance principle)

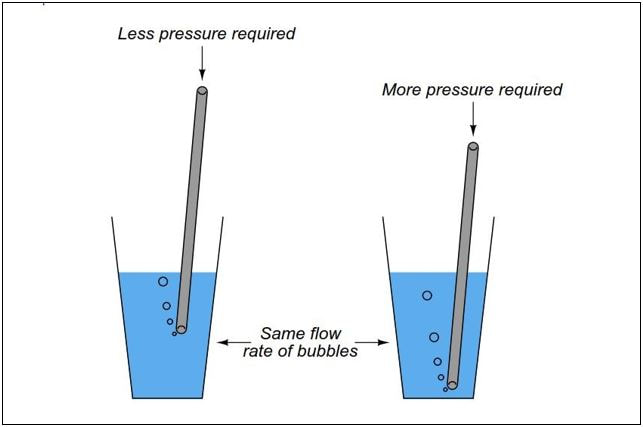

A very simple system may be simulated by gently blowing air through a straw into a glass of water, maintaining A STEADY RATE OF BUBBLES exiting the straw while changing the depth of the straw’s end in the water.

The hydro-static pressure of the water at the straw’s tip becomes translated into air pressure in your mouth as you blow, since the air pressure must just exceed the water’s pressure in order to

escape out the end of the straw.

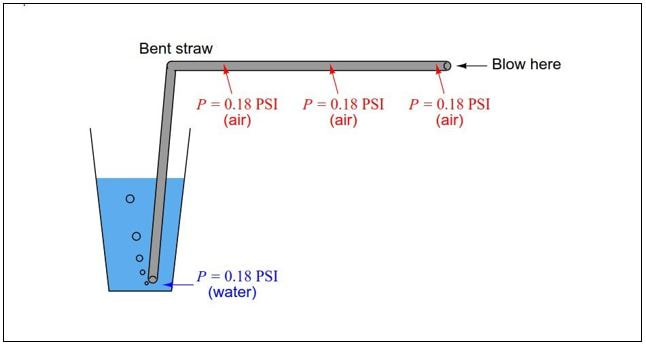

So long as the flow rate of air is modest (no more than a few bubbles per second), the air pressure will be very nearly equal to the water pressure, allowing measurement of water pressure (and therefore water depth) at any point along the length of the air tube.

Basics of Purging will get clear in this introduction (*1) and then the Analogy with Weighing scale (force balance principle)

A very simple system may be simulated by gently blowing air through a straw into a glass of water, maintaining A STEADY RATE OF BUBBLES exiting the straw while changing the depth of the straw’s end in the water.

The hydro-static pressure of the water at the straw’s tip becomes translated into air pressure in your mouth as you blow, since the air pressure must just exceed the water’s pressure in order to

escape out the end of the straw.

So long as the flow rate of air is modest (no more than a few bubbles per second), the air pressure will be very nearly equal to the water pressure, allowing measurement of water pressure (and therefore water depth) at any point along the length of the air tube.

If we lengthen the straw and measure pressure at all points throughout its length, it will be the same as the pressure at the submerged tip of the straw

THIS IS THE WORKING FOR N2 PURGING OF IMPULSE LINES.

Now below are common questions.

BUT HOW DO WE KNOW WHETHER BUBBLES ARE GOING OUT OR NOT ? THE TANK IS NOT TRANSPARENT ?

WILL THE LIQUID NOT FILL IN THE IMPULSE LINES EVEN IF PRESSURE INCREASES ? HOW IS THIS POSSIBLE ?

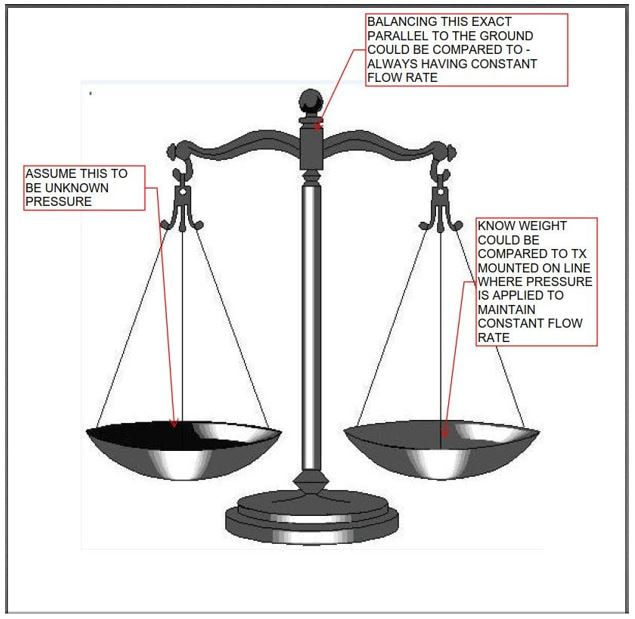

Analogy of Vendor weighing machine is what I relate to remember this concept maybe this could be helpful to you

THE ANSWER IS WE DON’T SEE THE BUBBLES ENTERING THE TANK WE JUST KEEP THE FLOW RATE CONSTANT AND EVERYTHING ELSE WILL TAKE CARE ON ITS OWN.

Let’s compare to weighing machine !!!

The weighing machine has two sides and a rod (pointer in middle) that has to be balanced One side of the weighing machine is where unknown weight is put .

Vendor doesn’t know what weight it is but his aim is to BALANCE THE POINT so he puts KNOWN weight on the other side TILL THE POINTER IS AT THE MIDDLE .

I know it sounds crazy but impulse line purging works the same way !!!! yes let me explain

The pressure on process connection is not known (LIKE the side of weighing machine with unknown weight )

OUR AIM IS CONSTANT FLOW RATE (Like Balancing the pointer of weighing scale )

Now below are common questions.

BUT HOW DO WE KNOW WHETHER BUBBLES ARE GOING OUT OR NOT ? THE TANK IS NOT TRANSPARENT ?

WILL THE LIQUID NOT FILL IN THE IMPULSE LINES EVEN IF PRESSURE INCREASES ? HOW IS THIS POSSIBLE ?

Analogy of Vendor weighing machine is what I relate to remember this concept maybe this could be helpful to you

THE ANSWER IS WE DON’T SEE THE BUBBLES ENTERING THE TANK WE JUST KEEP THE FLOW RATE CONSTANT AND EVERYTHING ELSE WILL TAKE CARE ON ITS OWN.

Let’s compare to weighing machine !!!

The weighing machine has two sides and a rod (pointer in middle) that has to be balanced One side of the weighing machine is where unknown weight is put .

Vendor doesn’t know what weight it is but his aim is to BALANCE THE POINT so he puts KNOWN weight on the other side TILL THE POINTER IS AT THE MIDDLE .

I know it sounds crazy but impulse line purging works the same way !!!! yes let me explain

The pressure on process connection is not known (LIKE the side of weighing machine with unknown weight )

OUR AIM IS CONSTANT FLOW RATE (Like Balancing the pointer of weighing scale )

Lets take 2 cases

OUR AIM :- Let us assume we need a flow rate of 1L/m (This is measured with help of rotameter )

This flow is decided in such a way that the pressure applied is very slightly more than process just so much that a bubble of purge gas goes in fluid such that process does not enter impulse

piping . (refer introduction concept of straw)

So Initially OUR APPLIED PRESSURE = (Approximately very closed to) Process pressure just so much as a few (negligible) bubble can escape .

#CASE 1 - The process pressure increases

As pressure increase it will provided resistance to our flow and the flow rate will decrease to assume 0.5 L/m

So we will increase the pressure such that flow increase to 1L/m .

And this pressure which is increased when measure will closely correspond to the process pressure .

#CASE 2 - The process pressure decreases

As pressure decreases we it will provided less resistance to flow and the flow rate will increase to assume 1.5 L/m

So we will decrease the pressure applied so that the flow is reduced to 1 L/m

HENCE we place the Transmitter (In the same line ) to measure this pressure which corresponds to process pressure without actually coming in contact with fluid

PS: This is as per best of my understanding.

Reference :-

(*1)Introduction by Tony R Kuphaldt (Lessons in Industrial instrumentation) a very nice read !!!

OUR AIM :- Let us assume we need a flow rate of 1L/m (This is measured with help of rotameter )

This flow is decided in such a way that the pressure applied is very slightly more than process just so much that a bubble of purge gas goes in fluid such that process does not enter impulse

piping . (refer introduction concept of straw)

So Initially OUR APPLIED PRESSURE = (Approximately very closed to) Process pressure just so much as a few (negligible) bubble can escape .

#CASE 1 - The process pressure increases

As pressure increase it will provided resistance to our flow and the flow rate will decrease to assume 0.5 L/m

So we will increase the pressure such that flow increase to 1L/m .

And this pressure which is increased when measure will closely correspond to the process pressure .

#CASE 2 - The process pressure decreases

As pressure decreases we it will provided less resistance to flow and the flow rate will increase to assume 1.5 L/m

So we will decrease the pressure applied so that the flow is reduced to 1 L/m

HENCE we place the Transmitter (In the same line ) to measure this pressure which corresponds to process pressure without actually coming in contact with fluid

PS: This is as per best of my understanding.

Reference :-

(*1)Introduction by Tony R Kuphaldt (Lessons in Industrial instrumentation) a very nice read !!!