PMI stands for Positive material Identification basically we check the material content

Material Certificate as name suggests also describes the material content

so what is the difference between them ?

When we have especially Higher Grade materials like Alloy C-276 etc.

We ask for Material Certificate and PMI both but WHY ??

Is there a logical need for it.

Let have a milkshake and eventually figure it out.

Material Certificate as name suggests also describes the material content

so what is the difference between them ?

When we have especially Higher Grade materials like Alloy C-276 etc.

We ask for Material Certificate and PMI both but WHY ??

Is there a logical need for it.

Let have a milkshake and eventually figure it out.

Milkshake example

Suppose you need milkshake of 1000 liters from a milkshake vendor

And you want the sugar to be used of Grade A in milkshake.

But in order to be sure that the milkshake vendor uses Grade A sugar and not the cheap sugar you do two things

STEP 1 :- You ask the Vendor to submit the Detail bill (like material certificate) of sugar purchased from wholesaler (D-MART etc) to ensure vendor has bought Grade A sugar .

Now :- When you receive 1000 tons of milkshake there could be a chance that vendor bought the Grade A sugar from D-MART but did not use it in you milkshake and used some cheap quality

STEP 2 :- So you run a test (like PMI) in milkshake sample or entire lot to know whether grade A sugar was put in it or not .

Same is with PMI the PMI could be done on few tags or entire lot of tags ( Also referred as 100% of Tags) or 10% of tags etc depending on criticality etc.

Example in one of my project for Bolts only 10% of the lot would undergo PMI was finalized and agreed by client so cost could be minimized .

And you want the sugar to be used of Grade A in milkshake.

But in order to be sure that the milkshake vendor uses Grade A sugar and not the cheap sugar you do two things

STEP 1 :- You ask the Vendor to submit the Detail bill (like material certificate) of sugar purchased from wholesaler (D-MART etc) to ensure vendor has bought Grade A sugar .

Now :- When you receive 1000 tons of milkshake there could be a chance that vendor bought the Grade A sugar from D-MART but did not use it in you milkshake and used some cheap quality

STEP 2 :- So you run a test (like PMI) in milkshake sample or entire lot to know whether grade A sugar was put in it or not .

Same is with PMI the PMI could be done on few tags or entire lot of tags ( Also referred as 100% of Tags) or 10% of tags etc depending on criticality etc.

Example in one of my project for Bolts only 10% of the lot would undergo PMI was finalized and agreed by client so cost could be minimized .

Practical "Valve" example

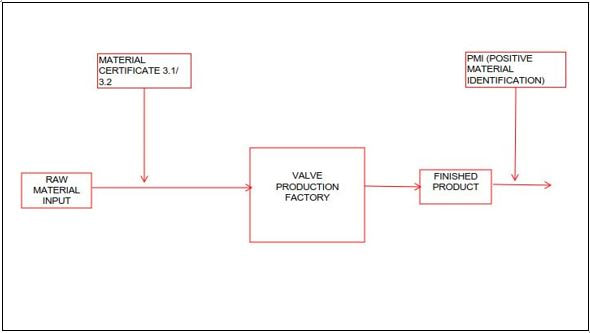

Suppose we want 100 Valve’s of Grade A so when the vendor buys the Material from the supplier the supplier produces a Certificate called material certificate 3.1 and after the Valve is manufactured to ensure that the same material is used and no mixing has taken place PMI test is done.

In Short Material certificate is for Material Quality of Raw material and PMI is for the finished product .

In Short Material certificate is for Material Quality of Raw material and PMI is for the finished product .

Material certificate is further divided

Material Certificate 3.1:- This in brief means :-This certificate given by the manufactures own representative who was not involved in manufacturing process himself

Material Certificate 3.2 :- Here a 3rd party (independent inspection authority) is involved which checks the material and the certificate is provided

Its is also sometimes referred as CMTR :- Certified Material test Report

Thanks for reading!!!

Credits :- Thanks a lot to Satish Sohani for explaining this concept to me !

PS: This is as per best of my understanding !