Why is BETA ratio limit required

Have you ever wondered from where do we get this beta numbers from and why we must keep the BETA ratio in orifice calculation in between these two Values?

Let us start with understanding what is Beta Ratio and then lets get rebellious and take “Extreme cases” where we don’t follow these limits.

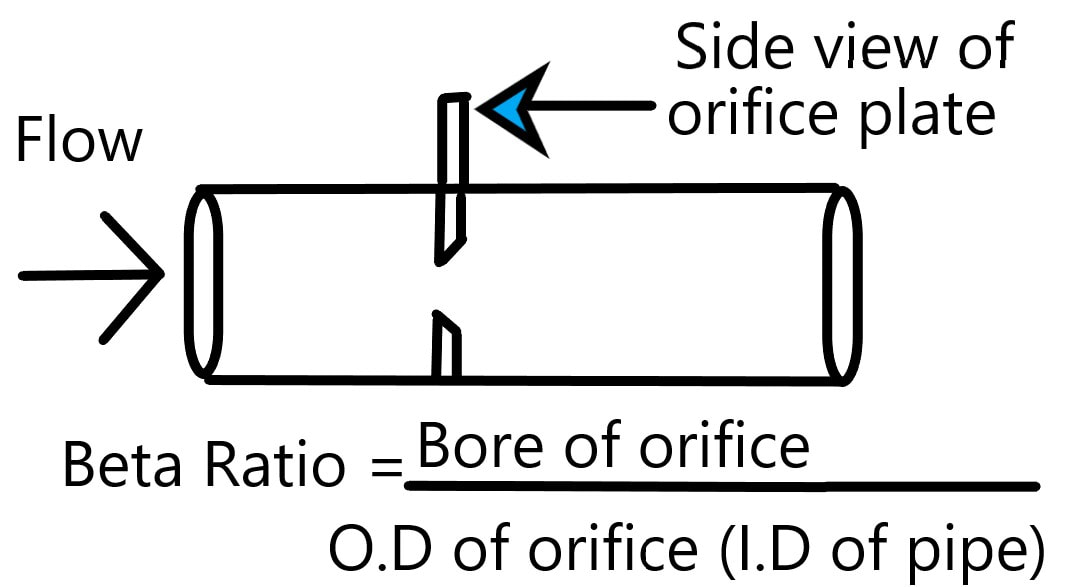

It has a very simple self explanatory equation and is as follows

Let us start with understanding what is Beta Ratio and then lets get rebellious and take “Extreme cases” where we don’t follow these limits.

It has a very simple self explanatory equation and is as follows

For experimental purpose .Lets take “Extreme cases”

What if we take a BETA of 1

This is Possible if I.D of orifice =O.D of Orifice

But that means there is no restriction to flow so no Pressure Drop.

And Flow measurement is not possible if we have no pressure drop

Hence Beta ratio of 1 is not possible.

But that means there is no restriction to flow so no Pressure Drop.

And Flow measurement is not possible if we have no pressure drop

Hence Beta ratio of 1 is not possible.

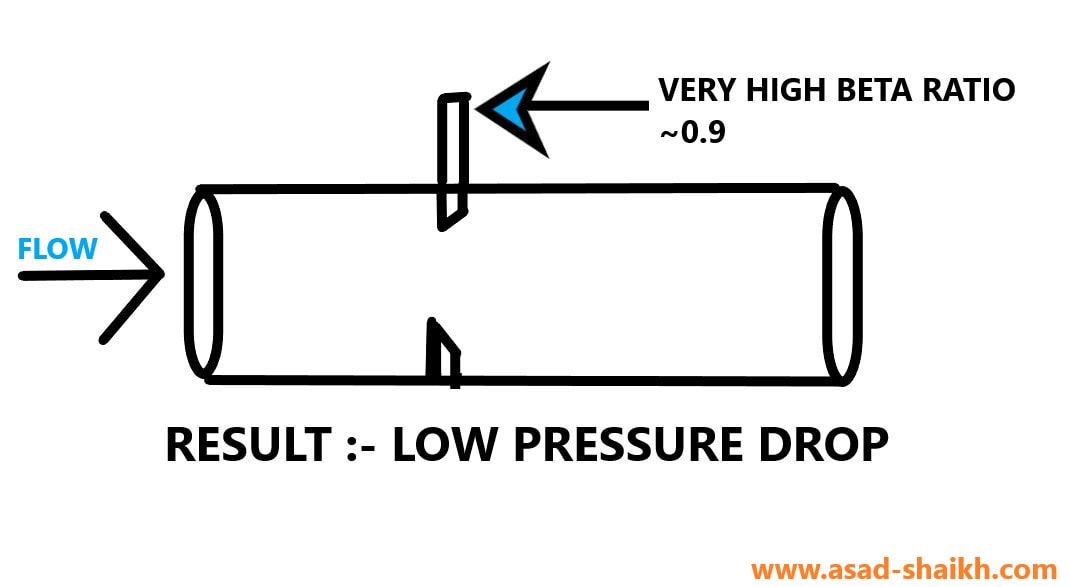

What if we take a BETA of 0.9

This is Possible if I.D of orifice is approximately near to O.D of Pipe

But that means there is very little restriction to flow so very little Pressure Drop.

And at low pressure drop it is difficult to measure and get required accuracy so we don’t go beyond 0.7

Also "Uncertainty increases “at such high beta ratio, This is an amazing concept that often gets overlooked and this is explained in detail in the coming passage with a simple graph from API MPMS 14.3.1 standard

But that means there is very little restriction to flow so very little Pressure Drop.

And at low pressure drop it is difficult to measure and get required accuracy so we don’t go beyond 0.7

Also "Uncertainty increases “at such high beta ratio, This is an amazing concept that often gets overlooked and this is explained in detail in the coming passage with a simple graph from API MPMS 14.3.1 standard

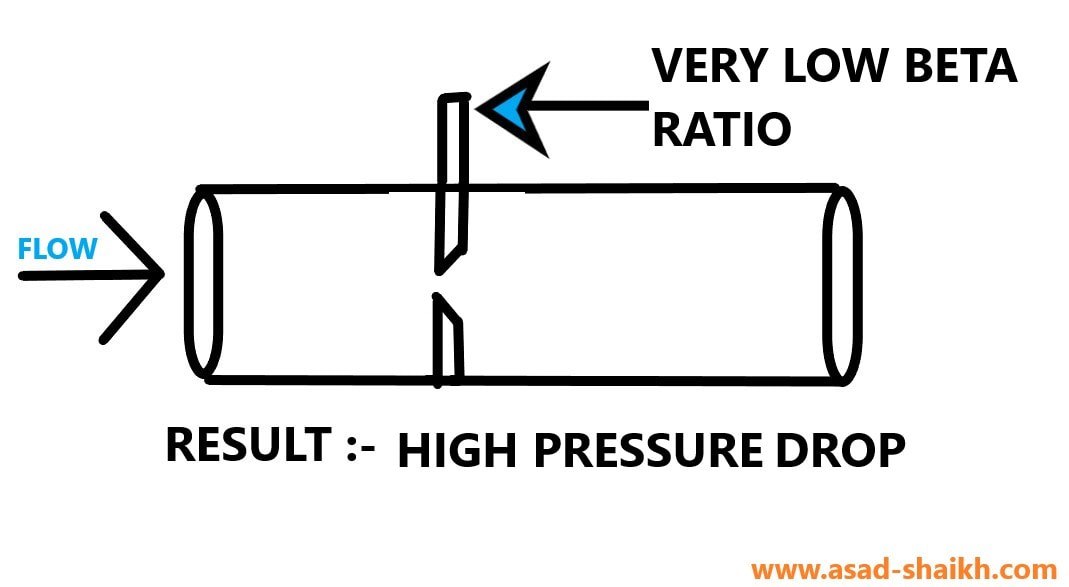

What if we take a BETA of 0.1?

This is Possible if I.D of orifice is very small as compared to O.D of Orifice

But that means there is very High restriction to flow so very High Pressure Drop.

This seems Good Right? High Pressure Drop means it will be easy to measure?

This is not the only consideration we have while sizing orifice.

Beta Ratio has an effect o variety of parameters (Few reasons are listed below)

But that means there is very High restriction to flow so very High Pressure Drop.

This seems Good Right? High Pressure Drop means it will be easy to measure?

This is not the only consideration we have while sizing orifice.

Beta Ratio has an effect o variety of parameters (Few reasons are listed below)

1) Process Hydraulics

This Affects Process Hydraulic calculation and also leads to Inefficiency in process as a whole.

As the PUMP will have to PUMP more!! As a result Process people in their Datasheet specify maximum allowable Pressure loss in Orifice.

What is the use of purposefully creating more restriction and then trying to compensate it with more pumping power!

As the PUMP will have to PUMP more!! As a result Process people in their Datasheet specify maximum allowable Pressure loss in Orifice.

What is the use of purposefully creating more restriction and then trying to compensate it with more pumping power!

2) Higher probability of cavitation and flashing

The more we drop the pressure the more is the chances of liquid to reach “Vapor Pressure”

And thus the chances for “Cavitation and Flashing” is more

Next important consideration

And thus the chances for “Cavitation and Flashing” is more

Next important consideration

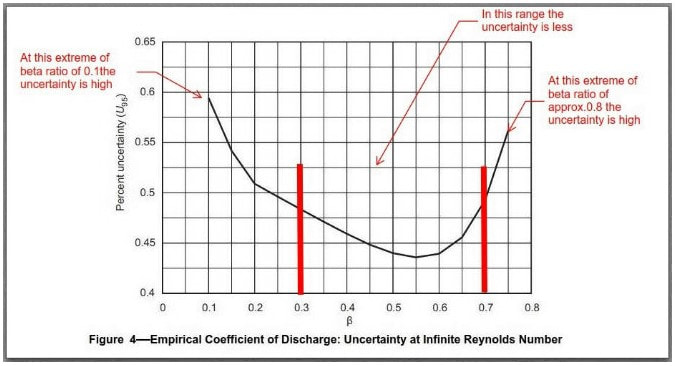

3) Coefficient of discharge (Uncertainty increases at extreme beta ratios)

COEFFICIENT OF DISCHARGE (UNCERTIANITY)

In simple words Cd (Uncertainty) is a function of Reynolds Number & Diameter ratio

The same definition by API is as follows

The estimated uncertainty of the empirical coefficient of discharge for concentric, square-edged, flange-tapped orifice meters that are in compliance with this standard

(API 14.3.1) is a function of the Reynolds number and the diameter ratio (β)(Reference API Manual of Petroleum Measurement Standards Chapter 14.3.1 Page no 31)

However at very high Reynolds numbers (approx. greater than 1,00000) the uncertainty is only a function of the diameter ratio(BETA) (β)

So here’s where Beta Ratio again comes into picture

Below is graph from API Standards Chapter 14.3.1 that has Percent Uncertainty Vs Beta Ratio (See Comments in Red)

In simple words Cd (Uncertainty) is a function of Reynolds Number & Diameter ratio

The same definition by API is as follows

The estimated uncertainty of the empirical coefficient of discharge for concentric, square-edged, flange-tapped orifice meters that are in compliance with this standard

(API 14.3.1) is a function of the Reynolds number and the diameter ratio (β)(Reference API Manual of Petroleum Measurement Standards Chapter 14.3.1 Page no 31)

However at very high Reynolds numbers (approx. greater than 1,00000) the uncertainty is only a function of the diameter ratio(BETA) (β)

So here’s where Beta Ratio again comes into picture

Below is graph from API Standards Chapter 14.3.1 that has Percent Uncertainty Vs Beta Ratio (See Comments in Red)

So from this graph we can deduce it is better to come to a nearby moderate value of BETA approx=0.5 for better accuracy !!

Lastly one unanswered question?

Lastly one unanswered question?

Why only between 0.2 to 0.6

There is no hard and fast rule it is just due to above reasons we try to stay in the moderate range, this limit is established by “Empirical” Method (That is by experimental means, we have come to this value).

Some standards say we should be between 0.2 to 0.6

While few suggest beta ratio between 0.1 to 0.7

None the less, stay Safe and select a moderate value

Thanks for Reading !!

Hope you found it valuable.

You can also download the PDF version of the article for future use.

Some standards say we should be between 0.2 to 0.6

While few suggest beta ratio between 0.1 to 0.7

None the less, stay Safe and select a moderate value

Thanks for Reading !!

Hope you found it valuable.

You can also download the PDF version of the article for future use.

| pdf_-why_is_beta_ratio_limit_required.pdf |

Further reading - Free E-book

Here's free E-book on diaphragm seals which covers gasket selection , Flange selection , Material selection and a ton of useful insights straight from the industrial world.

Almost a year was spend on creating this E-book and I have high hopes that you would find it useful and interesting.

Here's the link to download your copy

Almost a year was spend on creating this E-book and I have high hopes that you would find it useful and interesting.

Here's the link to download your copy